In the realm of fluid control and automation, valves play a crucial role in regulating the flow of liquids and gases. Among the various types, bi stable solenoid Valves have gained significant attention as an alternative to traditional valves. Understanding the differences between bi stable solenoid Valves and conventional valve technologies is essential for industries seeking efficient, reliable, and cost-effective solutions.

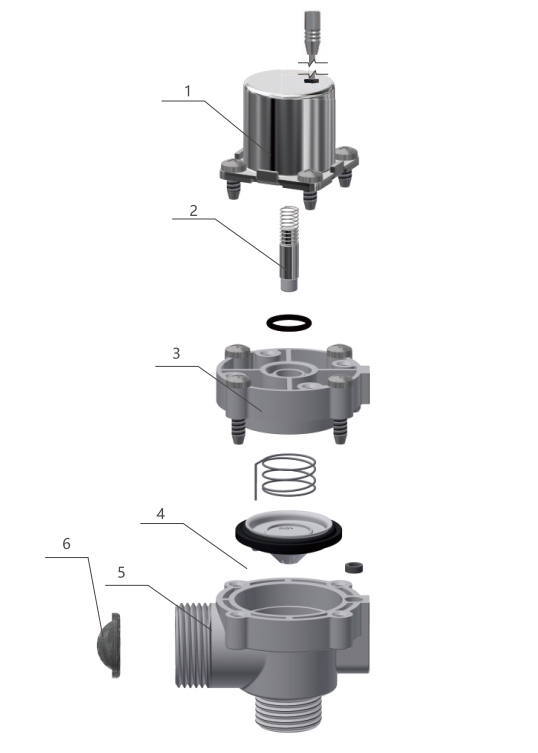

At its core, a bi stable solenoid Valve is designed with two stable positions—open and closed—without the need for continuous power to maintain either state. This feature differentiates it from traditional solenoid valves, which typically require constant power to remain open or closed. The ability of a bi stable solenoid Valve to maintain position without energy consumption s to significant energy savings and reduces heat generation in the system.

One of the key advantages of bi stable solenoid Valves is their energy efficiency. Since power is only used during the switching between states, these valves consume less electricity over time compared to traditional valves. This characteristic is especially beneficial in applications where valves remain in one position for extended periods. As a result, industries employing bi stable solenoid Valves often see reduced operating costs and improved sustainability.

Another notable distinction lies in the reliability and durability of bi stable solenoid Valves. Because they do not rely on continuous power to hold position, these valves experience less thermal stress and electrical wear. Traditional valves, constantly energized during operation, are more prone to overheating and coil burnout. Consequently, the use of bi stable solenoid Valves can to longer service life and fewer maintenance interventions.

The switching speed and operational noise also vary between the two valve types. While traditional solenoid valves generally provide rapid switching, bi stable solenoid Valves offer comparable performance with the added benefit of stable holding positions. Moreover, bi stable solenoid Valves tend to produce less noise during operation, which can be advantageous in noise-sensitive environments.

From an installation and control standpoint, bi stable solenoid Valves often simplify system design. Because these valves do not require continuous electrical input, the wiring and power supply demands are reduced. This simplification can lower initial installation costs and improve system reliability by minimizing electrical failures.

Despite their advantages, bi stable solenoid Valves may not be suitable for every application. Traditional valves might be preferred in scenarios requiring rapid, frequent switching or where continuous valve positioning control is necessary. Additionally, initial costs for bi stable solenoid Valves can be higher due to more complex internal mechanisms. However, many users find that the long-term energy savings and reduced maintenance offset these upfront expenses.

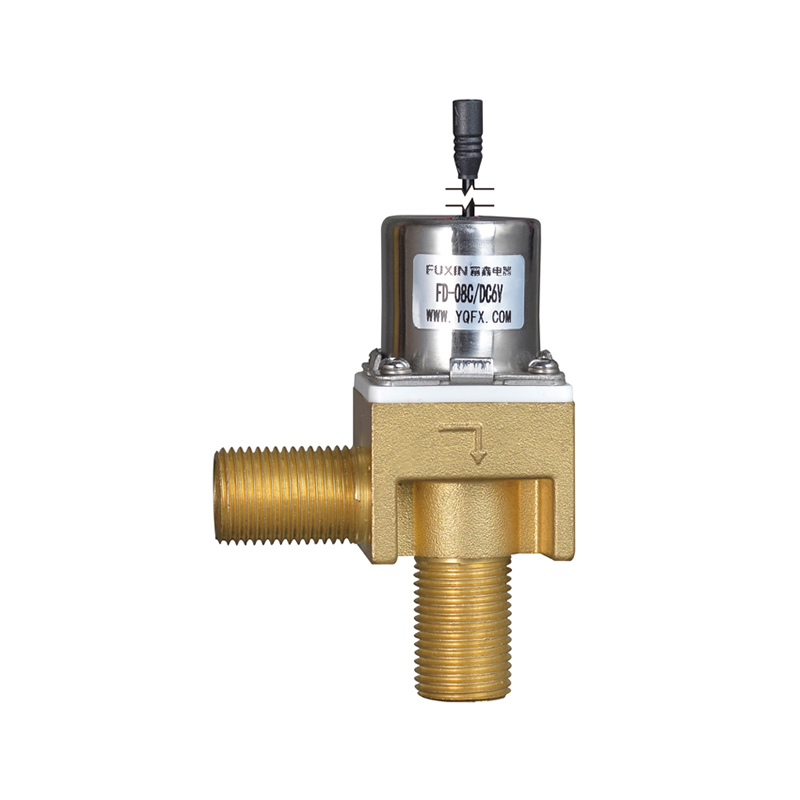

In terms of industry applications, bi stable solenoid Valves are gaining traction in sectors like HVAC, water management, automotive systems, and medical devices. These fields benefit from the valves’ low power consumption, reliability, and stable positioning. Conversely, traditional valves remain widely used in applications with high cycling demands, such as in pneumatic control and hydraulic systems.

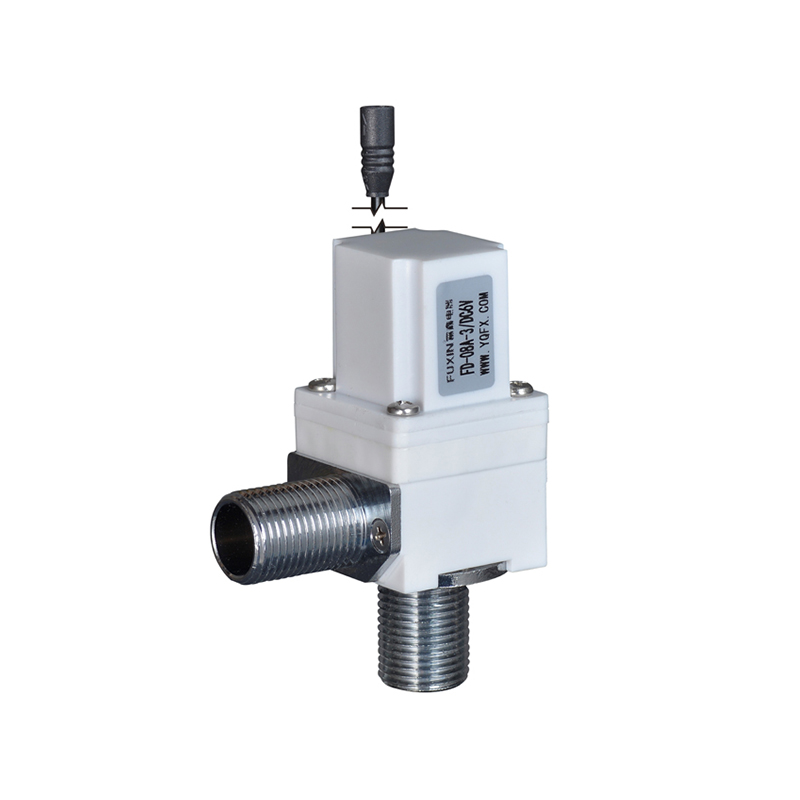

Recent technological advancements have further enhanced bi stable solenoid Valve performance. Manufacturers are incorporating improved magnetic materials, compact designs, and better sealing technologies to expand their usability. Integration with smart control systems and IoT platforms is also becoming more common, allowing real-time monitoring and automated control of bi stable solenoid Valves within complex industrial networks.

In conclusion, understanding the distinctions between bi stable solenoid Valves and traditional valves helps businesses make informed decisions when selecting valve solutions. While traditional valves offer rapid switching and simplicity, bi stable solenoid Valves provide energy efficiency, reduced maintenance, and reliable position holding. Assessing specific application requirements is crucial to determining which valve type will deliver performance and cost-effectiveness. As industries continue to focus on sustainability and operational efficiency, bi stable solenoid Valves are likely to play an increasingly important role in fluid control systems.

EN

EN English

English Español

Español