In the rapidly advancing world of industrial automation, engineering solenoid valves have emerged as a fundamental component driving efficiency, precision, and reliability in numerous applications. These valves, which are electrically controlled and powered by a solenoid, are used to regulate the flow of fluids and gases in various engineering processes. From manufacturing to energy production, engineering solenoid valves play a crucial role in enabling automated control systems to function effectively and with high precision.

What are Engineering Solenoid Valves?

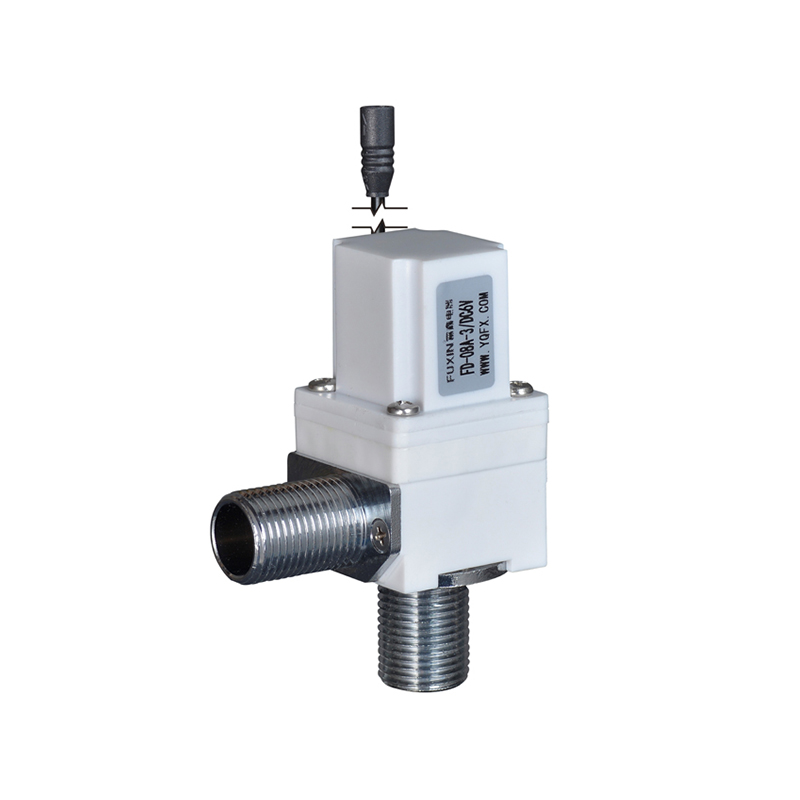

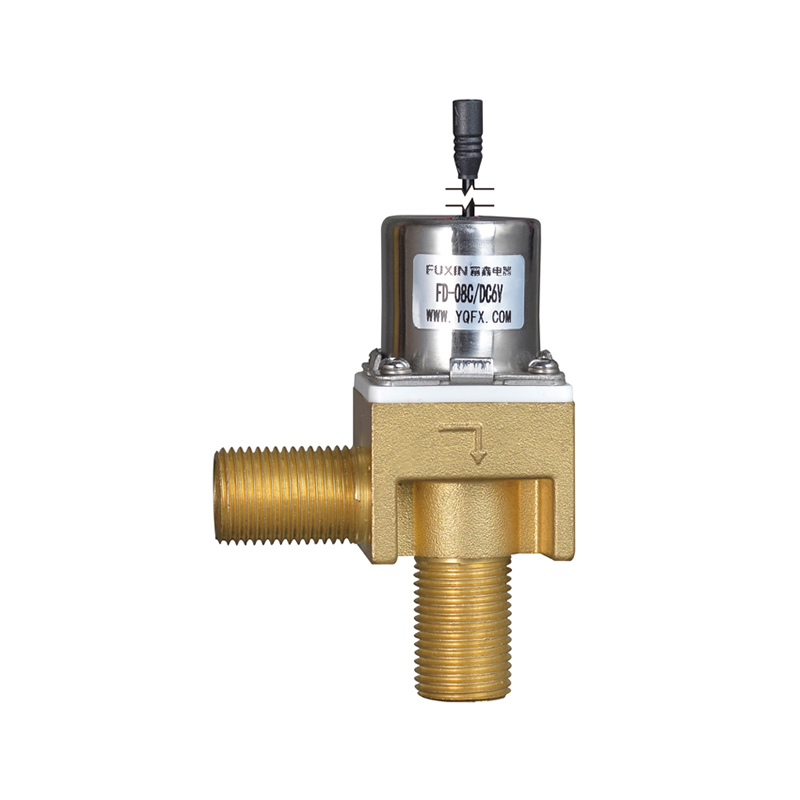

At its core, an engineering solenoid valve is a type of valve that uses an electromagnetic solenoid to control the opening and closing of the valve. When an electrical current is applied to the solenoid coil, it generates a magnetic field that either opens or closes the valve, allowing fluid or gas to flow through the system. The design and operation of these valves are essential for controlling the flow of liquids, gases, and even steam in a wide range of industrial systems.

The applications of engineering solenoid valves are vast and span numerous industries, including automotive manufacturing, energy, oil and gas, food and beverage, pharmaceuticals, and water treatment. As automation continues to gain ground across industries, these valves play an increasingly important role in ensuring process efficiency and safety.

The Role of Engineering Solenoid Valves in Industrial Automation

One of the main reasons for the widespread adoption of solenoid valves in industrial systems is their ability to enhance automation processes. In engineering applications, automation is a key driver of productivity and efficiency. Solenoid valves provide precise control over fluid and gas flow, enabling seamless operation of automated systems. By integrating solenoid valves with computerized systems and control panels, manufacturers can ensure that processes are carried out with the exact specifications required, without the need for manual intervention.

For example, in automated manufacturing, solenoid valves can control the flow of hydraulic or pneumatic fluids to various equipment, allowing machines to function efficiently and with minimal downtime. In a typical system, the solenoid valve regulates the activation of a specific machine or process, based on signals sent by sensors or a central control unit. This automation ensures that processes run smoothly, with reduced risk of errors or human intervention.

Benefits of Engineering Solenoid Valves

Precision Control

One of the standout features of engineering solenoid valves is their ability to provide highly precise control over the flow of fluids and gases. This is particularly important in industries where accuracy is paramount, such as pharmaceuticals, food processing, and chemical manufacturing. Solenoid valves are able to adjust flow rates with fine granularity, ensuring that materials are processed with the right quantities at the right time. This precision prevents waste and helps maintain product quality.

In many industries, stringent regulatory standards require precise control of fluid handling. Engineering solenoid valves help companies meet these requirements by offering consistent, repeatable performance, which is critical for maintaining high standards of quality and compliance.

Efficiency and Reduced Energy Consumption

Solenoid valves are known for their energy efficiency. Traditional mechanical valves can consume a significant amount of energy, especially when manual intervention is required to control the valve position. In contrast, solenoid valves only require electrical power to operate, and their compact design reduces the need for larger actuators or mechanical linkages. This not only saves space but also lowers the overall energy consumption of industrial systems.

Additionally, solenoid valves enable systems to operate only when necessary. For example, in applications such as water treatment plants or oil and gas pipelines, solenoid valves can be used to activate and deactivate systems automatically, based on real-time data. This prevents unnecessary energy expenditure and ensures that operations are carried out only when needed.

Reliability and Durability

In harsh industrial environments, equipment reliability is a top priority. Solenoid valves are designed to withstand tough conditions, including temperatures, high pressures, and exposure to corrosive substances. Made from high-quality materials like stainless steel and brass, engineering solenoid valves are built for durability and long service life. Their rugged design ensures that they perform reliably even in demanding environments such as oil refineries, chemical plants, and mining operations.

EN

EN English

English Español

Español