In the rapidly advancing world of industrial automation, Engineering Solenoid Valves are becoming increasingly indispensable. These valves, which are controlled by an electrical current, play a crucial role in regulating fluid or gas flow in a variety of systems. From manufacturing plants to medical equipment, Engineering Solenoid Valves have emerged as one of the essential components, ensuring efficient, reliable, and safe operations. This article explores the growing importance of these valves and their diverse applications across industries.

The Basics of Engineering Solenoid Valves

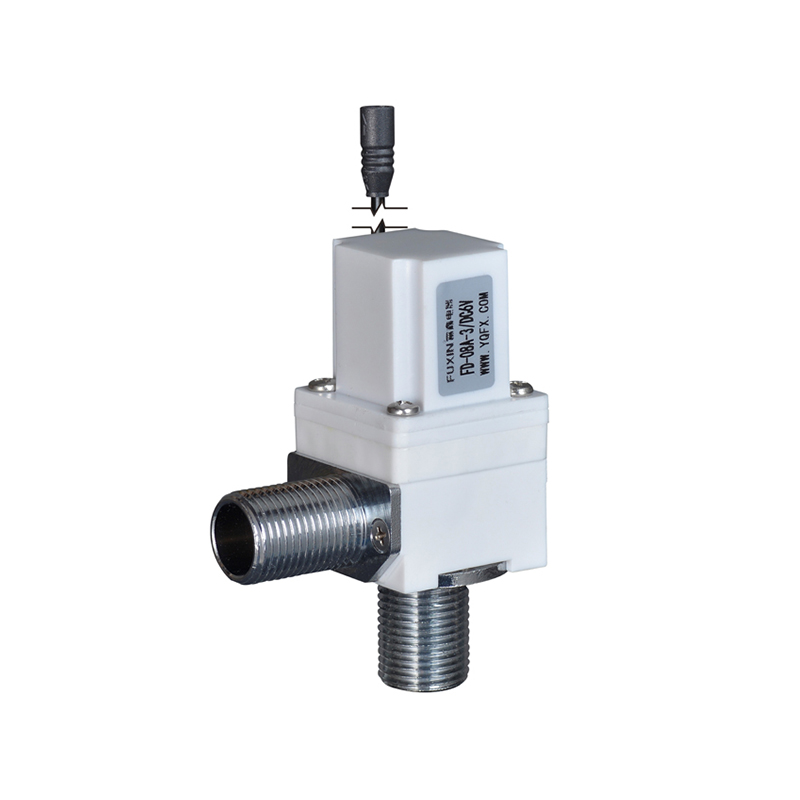

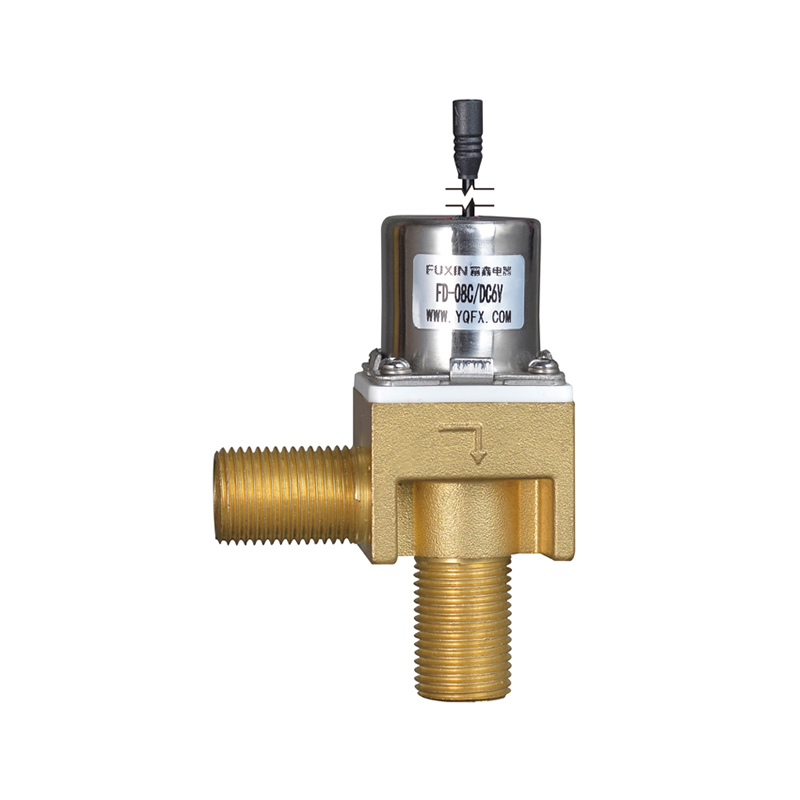

At the core, Engineering Solenoid Valves are electromagnetic devices used to control the flow of fluids or gases. They consist of a coil (solenoid) and a movable plunger or valve mechanism. When the coil is energized by an electric current, it creates a magnetic field that moves the plunger, opening or closing the valve. This on-off control allows Engineering Solenoid Valves to provide precise control over fluid dynamics in complex systems.

Due to their ability to automate processes without the need for manual intervention, Engineering Solenoid Valves are essential in systems where efficiency and accuracy are paramount. The design of these valves allows them to be operated remotely, providing a significant advantage in scenarios where human access to hazardous or hard-to-reach areas is limited.

Key Applications of Engineering Solenoid Valves

Manufacturing and Process Industries

In manufacturing plants, Engineering Solenoid Valves are used to control the flow of air, liquids, and gases within machinery and pipelines. These valves are particularly valuable in automated systems where consistent pressure and flow rates are necessary for performance. From controlling water flow in cooling systems to managing compressed air systems in assembly lines, these valves help streamline operations and improve production efficiency.

Automated Control Systems

The integration of Engineering Solenoid Valves in automated control systems has revolutionized industries such as automotive, packaging, and chemical production. These valves are often integrated into programmable logic controllers (PLCs), which allow for seamless monitoring and control. The precision offered by Engineering Solenoid Valves is crucial in ensuring that processes run smoothly without interruptions, thereby reducing downtime and increasing overall system reliability.

Agriculture and Irrigation Systems

The agriculture industry has also witnessed the growing adoption of Engineering Solenoid Valves in irrigation systems. These valves are used to control water flow to fields and crops, ensuring that plants receive the amount of water for growth. By automating the irrigation process, Engineering Solenoid Valves reduce the need for manual intervention, to more efficient water usage and lower operational costs.

Medical and Pharmaceutical Equipment

In the medical and pharmaceutical fields, Engineering Solenoid Valves are used in devices such as infusion pumps, anesthesia machines, and blood analysis equipment. These valves control the flow of fluids in these machines, ensuring that critical substances are delivered accurately and safely. The reliability of Engineering Solenoid Valves in such applications is of utimportance, as any malfunction could to catastrophic consequences.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on Engineering Solenoid Valves to regulate the flow of refrigerants and other gases. In larger buildings or industrial environments, HVAC systems must be capable of adjusting airflow to maintain temperature control. The efficiency of these systems is highly dependent on the precision of the solenoid valves used, making Engineering Solenoid Valves essential for maintaining the comfort and safety of building occupants.

Technological Advancements in Engineering Solenoid Valves

The evolution of Engineering Solenoid Valves has been closely tied to the broader trends in automation and technology. Recent innovations have focused on improving the durability, response time, and energy efficiency of these valves. For instance, the introduction of low-power solenoids has enabled Engineering Solenoid Valves to operate more efficiently, reducing the amount of energy required to operate them, which is especially valuable in industries that operate 24/7.

Moreover, advancements in materials have led to the development of solenoid valves that are resistant to corrosion, wear, and temperatures, expanding their applications in industries like oil and gas, where these conditions are prevalent. Some Engineering Solenoid Valves are now designed to withstand harsh chemicals, making them suitable for use in industries such as chemical processing and wastewater treatment.

EN

EN English

English Español

Español