Suppose you've ever used a sensor-activated faucet in a public restroom or encountered a smart toilet that flushes on its own. In that case, you have directly witnessed the seamless operation of a latching solenoid valve. These compact, often overlooked devices serve as the hidden muscle behind a vast array of automated fluid control systems we interact with in our daily lives. While their standard counterparts are common, the latching solenoid valve possesses distinct characteristics that make it a fine choice for many modern applications. But what fundamentally differentiates it from a regular solenoid valve, and why might it be the critical component for your next engineering or DIY project?

At its core, a latching solenoid valve operates on a simple yet brilliantly efficient principle. A standard solenoid valve requires a continuous application of electrical power to maintain its open or closed state; the moment the power is cut, a spring returns the valve to its default position. In stark contrast, a latching solenoid valve uses a brief, momentary electrical pulse to switch between its two states. Think of it like a bistable light switch: one quick flip turns the light on, and it remains on until another quick flip turns it off. This pulse-based mechanism is the key to its defining advantage: the valve consumes electrical energy only during the split-second it takes to change position. This results in remarkably low overall power consumption, making it exceptionally energy-efficient. This characteristic is not just a minor benefit; it is a game-changer for battery-powered applications, such as remote irrigation controllers, portable medical devices, or solar-powered systems, where energy drain is paramount for long-term, maintenance-free operation.

The practical benefits of a latching solenoid valve become abundantly clear when examining its diverse range of applications. Beyond the common examples in public sanitation, these valves are integral to modern irrigation systems, where they control water flow to different zones based on timer or sensor signals without draining the control unit's battery. They are also found in solar water heating systems, efficiently managing the circulation of heat-transfer fluids, and in various commercial appliances like coffee machines and water dispensers. Their ability to maintain a position (open or closed) without a constant electrical supply not only saves energy but also contributes to cooler operation, reducing thermal stress on the coil and other components. This inherently supports a longer functional lifespan. Furthermore, recognizing the demands of automated systems, manufacturers often design these components for high durability, with certain models rated for hundreds of thousands, or even millions, of cycles, ensuring reliability under frequent use.

When sourcing these critical components, the choice of a latching solenoid valve Manufacturer profoundly influences the product's performance, longevity, and safety. A reputable manufacturer with dedicated research, development, and testing facilities is more likely to deliver valves that meet stringent technical and regulatory standards, such as IP ratings for waterproofing or NSF certifications for potable water. For instance, some producers specialize in developing valves that can handle different water qualities, including those with slight impurities, or ones that operate reliably across a wide range of voltage conditions, offering crucial flexibility for global projects. The collaboration between a manufacturer's engineering team and the client during the development phase is particularly valuable. This partnership can help tailor a latching solenoid valve to particular needs, whether it involves a specific orifice size, a custom connector, or unique pressure ratings for a commercial appliance or a sophisticated residential water management system.

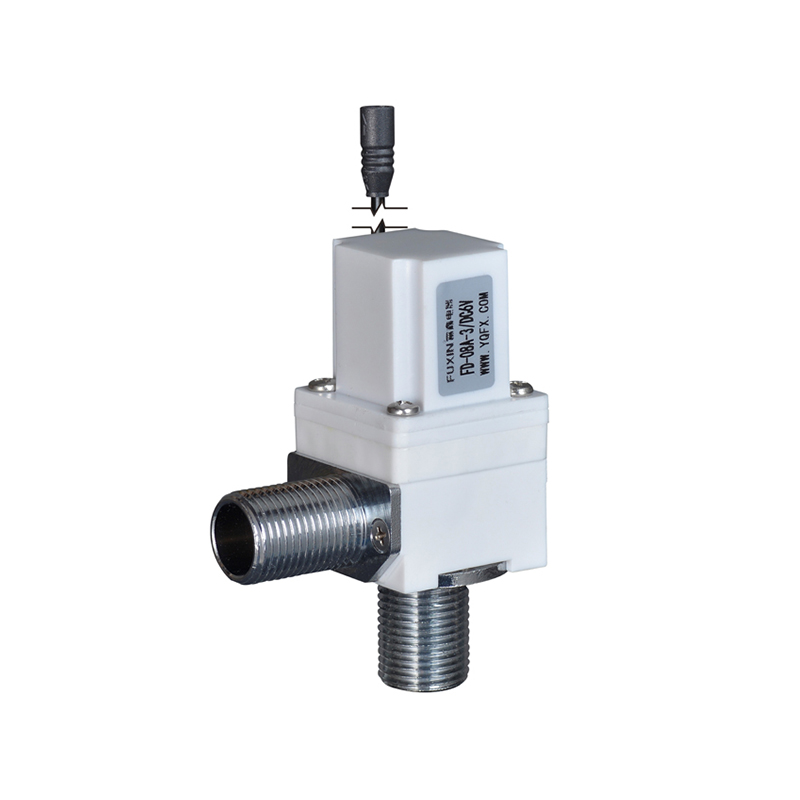

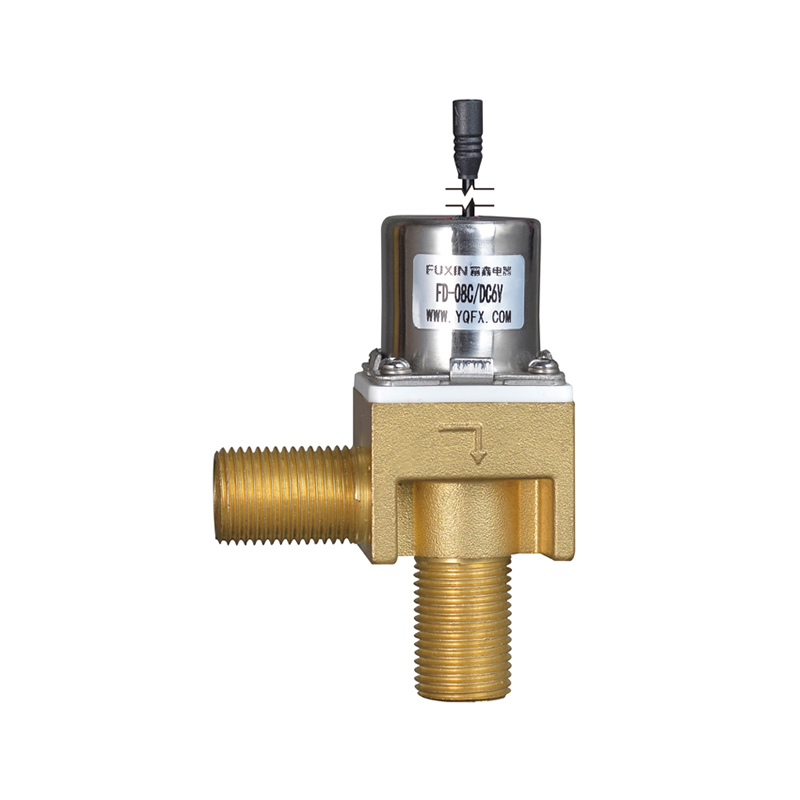

In terms of system integration, a well-designed latching solenoid valve typically offers straightforward installation. Many versions come with standardized connections (e.g., NPT threads) and are engineered to handle common pressure ranges found in residential and commercial settings. Their inherent compatibility with simple pulse signals from microcontrollers, timers, or sensors allows them to be seamlessly incorporated into existing control systems without requiring major modifications or complex driver circuits. This plug-and-play approach significantly simplifies the setup process for installers and system designers, accelerating deployment and reducing potential integration errors.

EN

EN English

English Español

Español