A Solenoid Coil is a fundamental component in many industrial and commercial systems, converting electrical energy into mechanical motion. This motion is used to operate valves, switches, and other equipment requiring precise actuation. The design of a solenoid coil affects performance factors such as response speed, energy consumption, and operational lifespan.

Working with a trusted Solenoid Coil Manufacturer ensures consistent quality, reliable material selection, and adherence to industrial standards. The right solenoid coil can improve system efficiency while minimizing maintenance requirements, which is critical in environments like automation, HVAC, and fluid control systems.

Key Features of Solenoid Coils

Modern Solenoid Coils are designed with performance and durability in mind. Their key features include:

- High Reliability: Designed for repeated operation, solenoid coils maintain consistent performance even under continuous duty.

- Energy Efficiency: Optimized winding and core design allow coils to operate with lower power consumption, suitable for battery or low-voltage systems.

- Thermal Resistance: Quality coils resist overheating, maintaining performance even in demanding applications.

- Precision Control: The magnetic field generated by a coil ensures smooth and precise movement of the actuator.

A professional Solenoid Coil Manufacturer can provide detailed specifications, including voltage, current rating, resistance, and duty cycle, which helps in selecting the right coil for any system.

Installation and Compatibility Considerations

Correct installation of a Solenoid Coil is crucial to system performance. Important factors include:

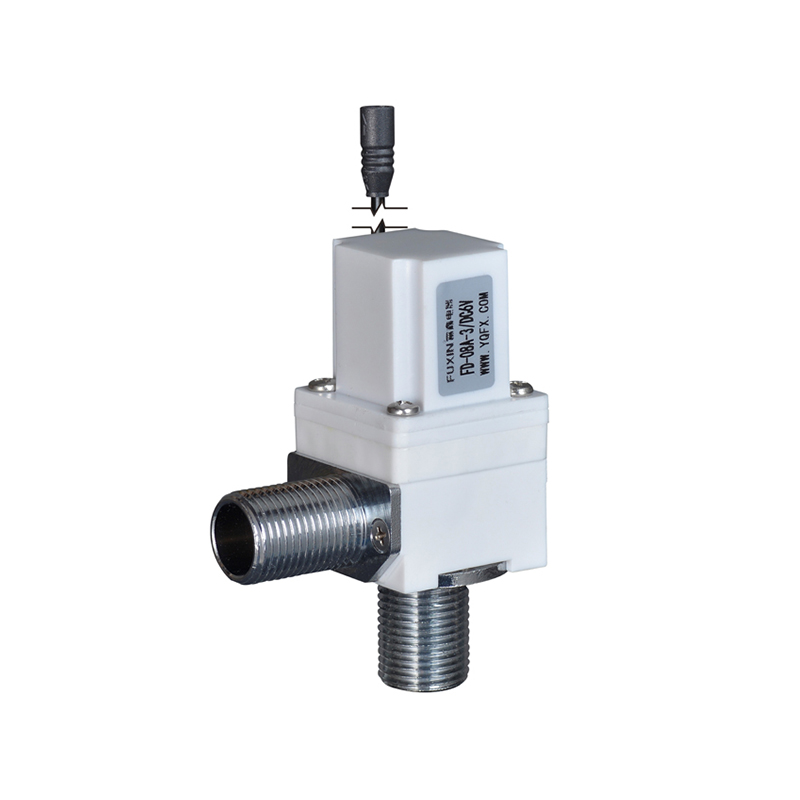

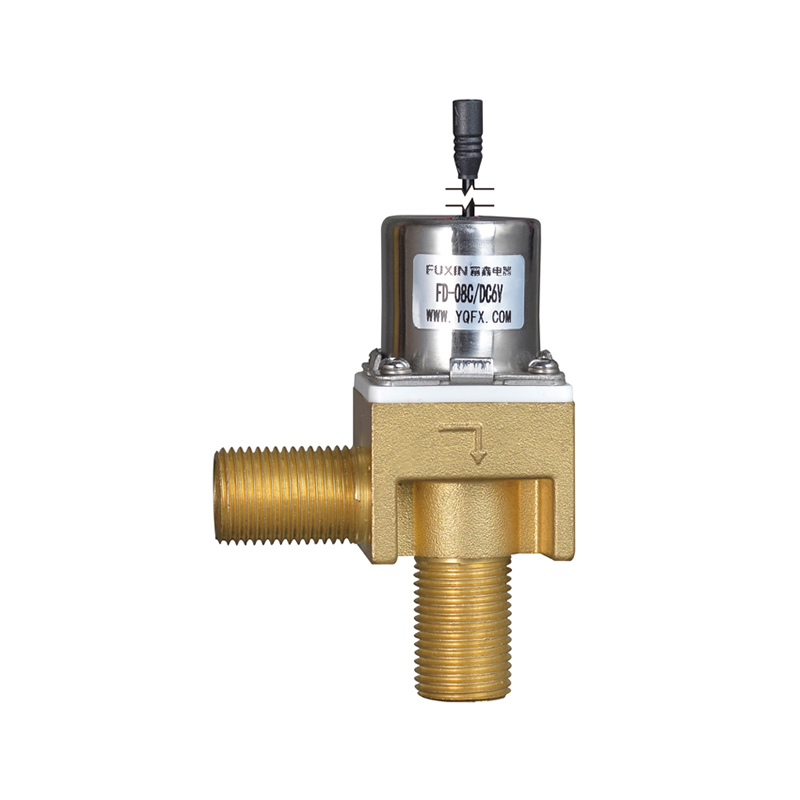

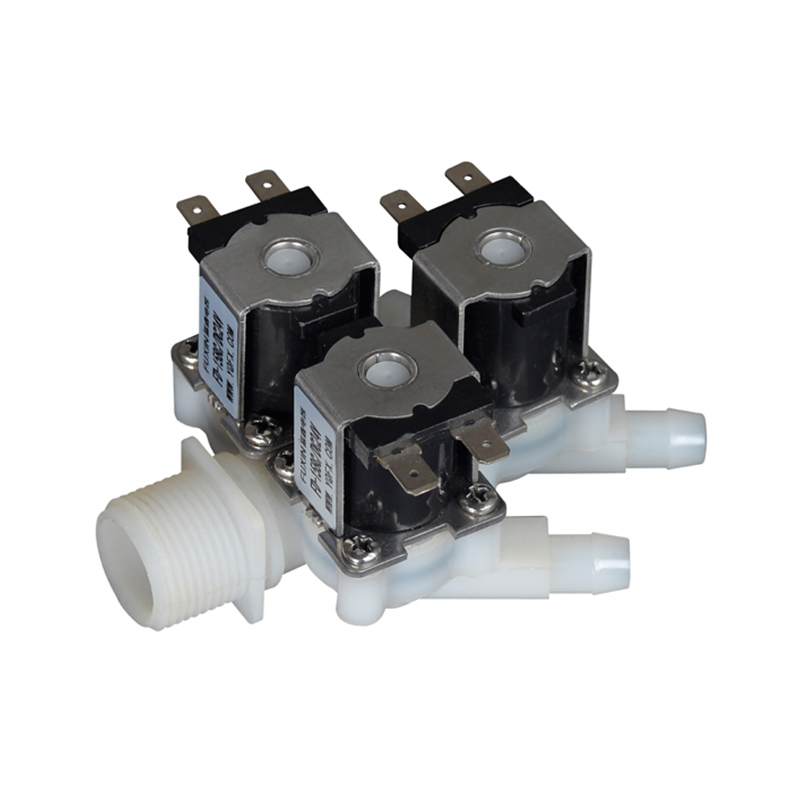

- Mounting Flexibility: Coils are available in multiple sizes and shapes to fit different valve or actuator designs.

- Core and Winding Quality: The material of the core and the coil winding affect magnetic force, temperature tolerance, and durability.

- Electrical Compatibility: Voltage and current specifications must match the controlling system to prevent overheating or failure.

Working closely with a Solenoid Coil Manufacturer ensures that the coil integrates seamlessly with existing equipment and meets technical requirements.

HVAC Systems: Controls airflow or fluid flow in heating and cooling systems.

- Automotive Systems: Operates fuel injectors, transmission valves, and other critical components.

- Water and Fluid Control: Controls solenoid valves in irrigation, plumbing, and processing applications.

- Medical Equipment: Ensures precise actuation in devices like pumps, ventilators, and diagnostic machines.

By selecting a reliable Solenoid Coil Manufacturer, engineers can source coils with consistent performance suitable for multiple applications, reducing downtime and operational issues.

Operational Performance and Longevity

The performance of a Solenoid Coil depends on design factors such as winding type, core material, and insulation. Properly designed coils:

- Deliver fast response times, critical for automation and process control.

- Operate under varying environmental conditions, including high temperature and humidity.

- Require minimal maintenance, especially in continuous duty applications.

A knowledgeable Solenoid Coil Manufacturer provides technical data and support to optimize coil selection for specific operational conditions, improving reliability and efficiency across systems.

Solenoid Coils are critical components in many industrial and commercial systems, offering precise control, energy efficiency, and reliable performance. Their versatility allows use in automation, fluid control, HVAC, automotive, and medical applications. Working with a reputable Solenoid Coil Manufacturer ensures access to high-quality coils with accurate specifications, consistent performance, and long operational life. Selecting the correct coil design can improve system efficiency, minimize maintenance, and support diverse operational needs across multiple industries.

EN

EN English

English Español

Español