A cartridge solenoid valve is designed to control fluid flow by combining a compact cartridge body with an electromagnetic actuator. The valve is usually installed directly into a manifold or valve block, which helps save space and reduces external piping. When electrical power is applied, the solenoid generates a magnetic field that moves an internal plunger. This movement opens or closes the flow path, allowing liquids or gases to pass through with controlled timing.

In sanitary ware systems, this structure is especially practical. Faucets, showers, toilets, and water-using appliances often have limited installation space. A cartridge design allows engineers to integrate flow control into the core structure without redesigning the entire plumbing layout. For manufacturers focused on sanitary and household applications, this type of valve supports consistent performance while keeping system layouts clean and organized.

From an operational view, the response time of a cartridge solenoid valve helps maintain stable flow behavior. Users experience steady water delivery without noticeable delay, which is important in daily-use fixtures where comfort and reliability matter.

Common Pain Points in Applications and Practical Solutions

Many system designers face challenges such as leakage risk, unstable flow, or difficulty fitting components into compact assemblies. A cartridge solenoid valve addresses these concerns by using sealed interfaces and standardized cavities. Once installed correctly, the valve body is supported by the manifold itself, which reduces vibration and stress during operation.

Another frequent concern is power usage. In household appliances and sanitary fixtures, valves may operate repeatedly throughout the day. A well-designed cartridge solenoid valve focuses on efficient electromagnetic action, allowing stable operation without unnecessary energy draw. This is useful for washing machines, dishwashers, and automated faucets where electrical efficiency is part of the overall product design.

Maintenance is also a topic engineers often consider. Cartridge-style valves simplify servicing because the internal unit can be removed without disassembling the entire system. This approach shortens inspection time and helps reduce system downtime in both residential and commercial installations.

Materials, Structure, and Manufacturing Considerations

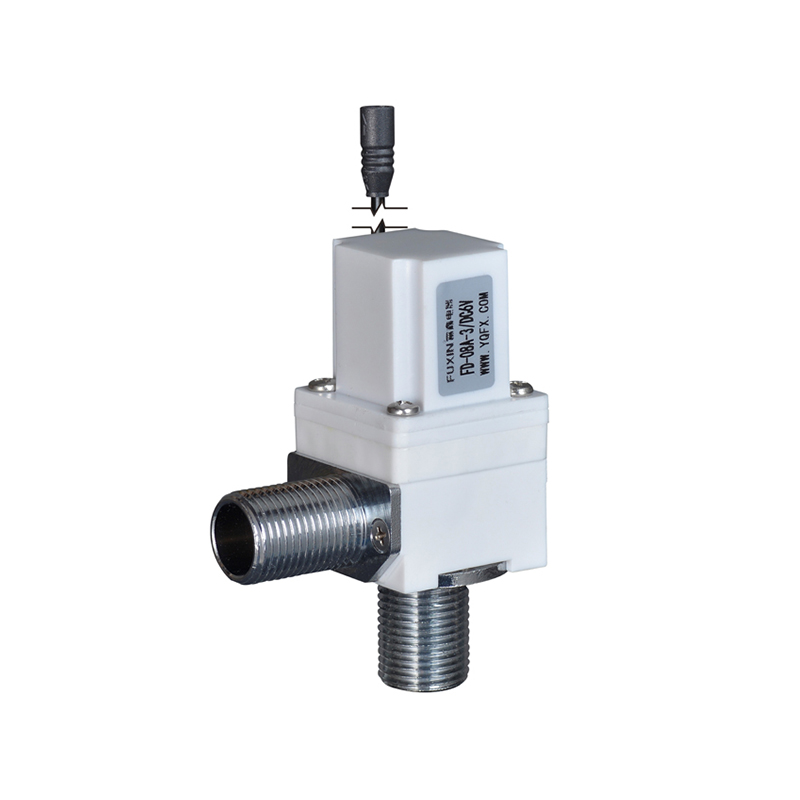

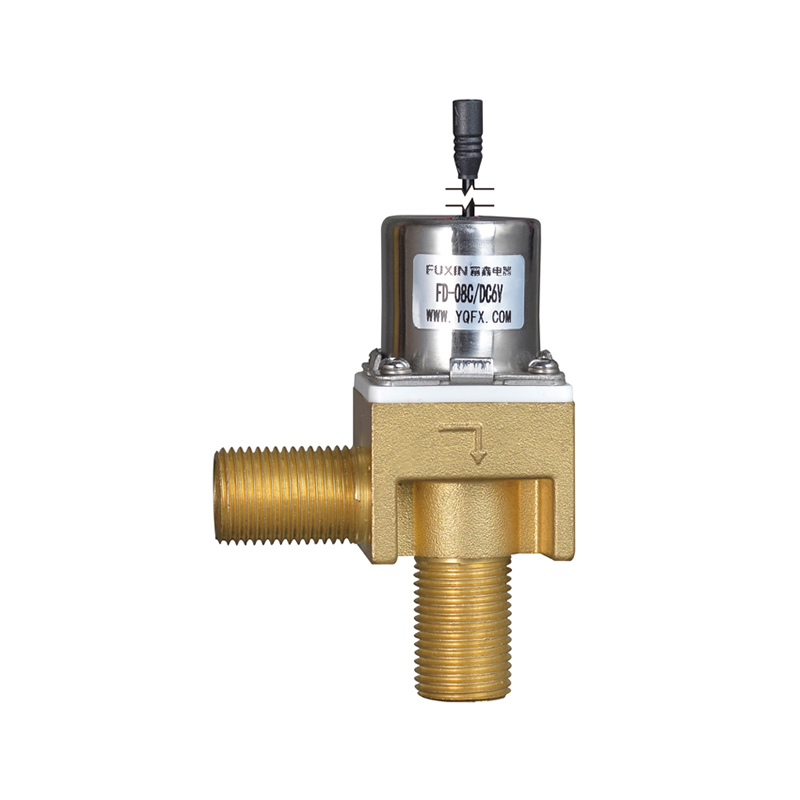

Material selection plays a direct role in how a cartridge solenoid valve performs over time. In sanitary ware environments, corrosion resistance and surface stability are important. Common materials include stainless steel, brass, and engineering plastics that can handle regular contact with water and cleaning agents.

From a production standpoint, a cartridge solenoid valve Manufacturer focuses on precision machining and consistent tolerances. The cartridge must fit the cavity accurately to avoid internal leakage and pressure loss. Coil winding quality also affects how smoothly the valve responds to electrical signals.

Manufacturers serving sanitary ware, household appliances, and engineering systems often offer different voltage options and pressure ratings. This flexibility allows the same cartridge concept to be adapted across faucets, irrigation systems, and automated equipment without changing the core design philosophy.

Application Scenarios Across Industries

A cartridge solenoid valve is widely used in sanitary ware systems because it blends easily into compact fixtures. Touch-free faucets, sensor-controlled showers, and water-saving toilet systems rely on precise flow control that fits inside limited housing space.

In household appliances, these valves help manage water intake and discharge. Washing machines and dishwashers depend on reliable opening and closing cycles to keep processes running smoothly. Engineering applications, including HVAC and fluid automation modules, also benefit from cartridge installation because it simplifies manifold design.

Working with a cartridge solenoid valve Manufacturer that understands these varied environments helps ensure the valve structure aligns with real usage conditions. Experience across the sanitary, appliance, and irrigation sectors often results in designs that balance durability, responsiveness, and installation convenience.

EN

EN English

English Español

Español