A Latching Solenoid Valve operates differently from conventional solenoid valves. Instead of requiring continuous power to remain open or closed, it changes position using a short electrical pulse. Once switched, the valve holds its position mechanically or magnetically without further energy input. This operating logic makes the Latching Solenoid Valve suitable for systems where power availability is limited or controlled carefully.

In sanitary applications, this behavior is valuable because it allows faucets and fixtures to maintain their state even during power interruptions. Users experience stable water control, while system designers gain flexibility in electrical planning. From an engineering standpoint, this pulse-based actuation also reduces heat generation within the coil, which supports consistent performance over repeated cycles.

Common Use Scenarios in Sanitary and Appliance Systems

Latching solenoid valves are often selected for sanitary ware such as sensor faucets, timed water outlets, and automated flushing systems. In these applications, water flow does not need constant electrical input once activated. The valve changes state only when a new signal is received, making it suitable for battery-powered or low-voltage installations.

Beyond sanitary fixtures, similar valve structures are also used in household appliances and engineering systems where controlled fluid movement is required. The shared requirement across these scenarios is a predictable response with limited electrical demand. For this reason, cooperation with a Latching Solenoid Valve Manufacturer usually starts with understanding how often the valve will switch and how long it is expected to remain in each position.

Structural Design and Material Selection

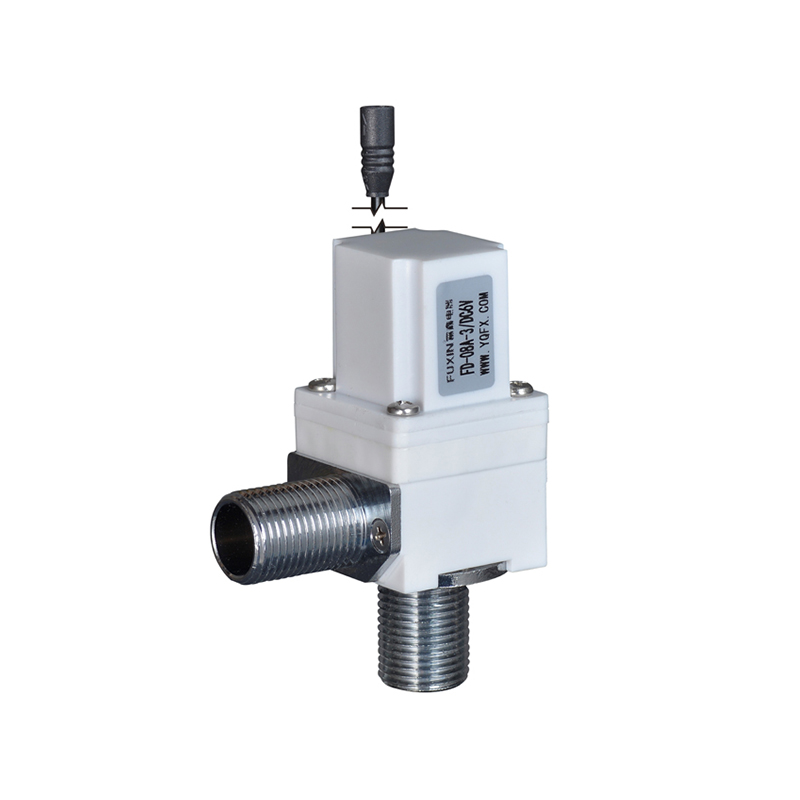

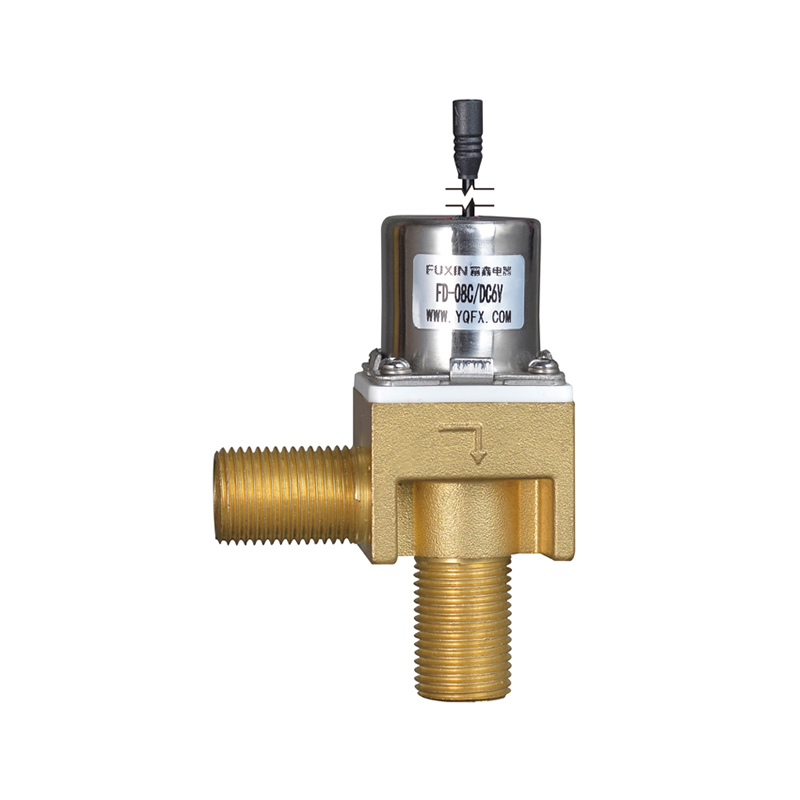

The internal structure of a Latching Solenoid Valve focuses on a balance between magnetic force and mechanical stability. Permanent magnets or specialized armature designs are commonly used to hold the valve position after actuation. This structure must remain stable across temperature changes and varying water pressure conditions.

Material selection also plays a role in long-term operation. Valve bodies are typically produced from brass, stainless steel, or engineered polymers to support resistance against corrosion and wear. Internal seals are chosen to maintain consistent closure without excessive friction. An experienced Latching Solenoid Valve Manufacturer often fine-tunes these elements based on specific sanitary or appliance requirements rather than offering a single generic design.

Integration With Control Systems and Installation Considerations

From a system integration perspective, latching solenoid valves must align with the control logic of the overall device. Control boards are programmed to send short pulses rather than continuous signals, which changes how wiring and timing are designed. This approach supports compact control units and simplifies power management in modern sanitary systems.

Installation also benefits from this design. Reduced power draw allows for thinner wiring and smaller power supplies, especially in distributed installations like public restrooms or modular sanitary units. Early communication with a Latching Solenoid Valve Manufacturer helps align electrical parameters, connector types, and mounting structures with the intended system layout.

Stability, Maintenance, and Production Consistency

In daily operation, a Latching Solenoid Valve is expected to switch reliably and remain stable between activations. Water quality, pressure variation, and usage frequency all influence long-term behavior. While routine maintenance is generally limited, internal cleanliness and material compatibility contribute to consistent movement over time.

From a manufacturing perspective, consistency across production batches is critical. Small variations in magnetic strength or internal clearances can affect switching behavior. This is why sanitary ware brands often prefer long-term cooperation with a trusted Latching Solenoid Valve Manufacturer who maintains controlled assembly processes and stable material sourcing.

By focusing on pulse-based operation, structural balance, and system compatibility, a Latching Solenoid Valve supports controlled water management in modern sanitary and appliance systems. Its value lies in efficient electrical usage, predictable response, and steady operation across a wide range of applications, making it a practical component for designs that prioritize controlled fluid handling without continuous power demand.

EN

EN English

English Español

Español