Precision fluid control has become essential in today's hydraulic and pneumatic systems. A cartridge solenoid valve plays a quiet yet critical role in maintaining efficiency and responsiveness within compact machinery. Unlike traditional valves, its cartridge-style design allows it to fit directly into a manifold cavity, reducing space requirements while improving serviceability. As demand grows across industries such as construction, agriculture, and automation, cartridge solenoid valve manufacturers are developing smarter, more durable designs to meet evolving expectations.

Compact Design with Strong Performance

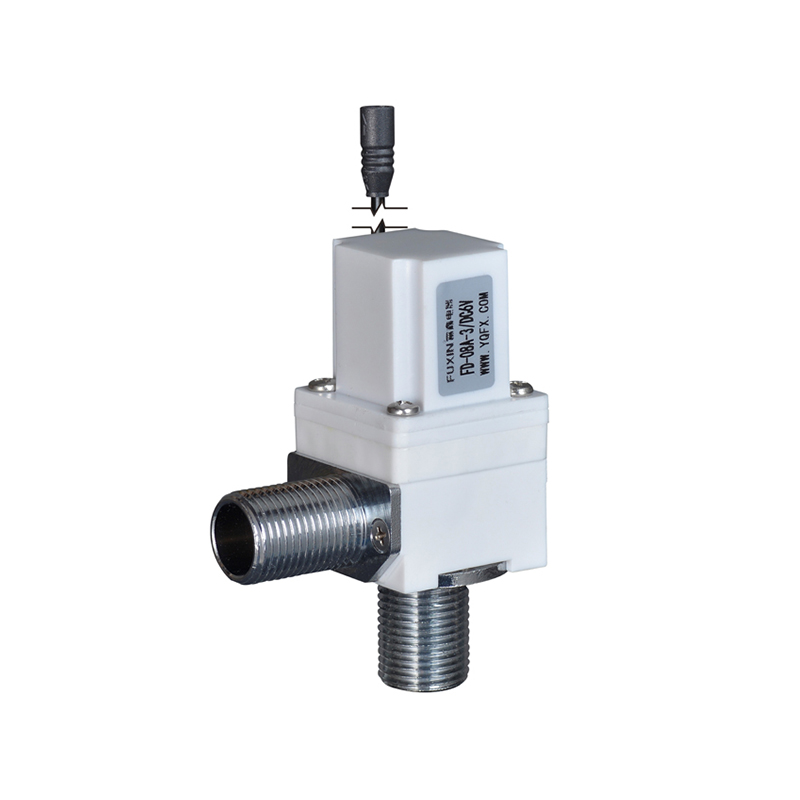

The cartridge solenoid valve is valued for its ability to deliver high performance in a limited space. It can control flow direction, pressure, or load holding while maintaining quick response times. Because of its modular construction, engineers can integrate it easily into a wide range of hydraulic circuits without reworking the entire system.

This design flexibility allows manufacturers to tailor the valve body, coil, and sealing materials based on the working environment- whether it's high pressure, corrosive fluid, or outdoor exposure. Many cartridge solenoid valve manufacturers also focus on reducing internal leakage and improving coil efficiency, which helps machines operate consistently under demanding conditions.

Material Selection and Durability

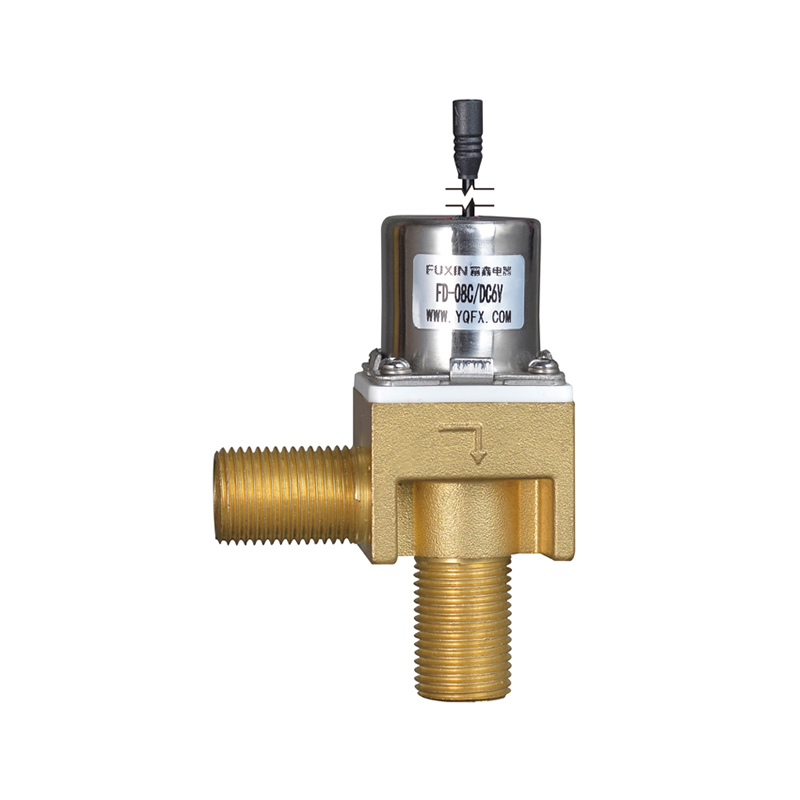

In industries where uptime is critical, valve durability matters just as much as precision. Reliable cartridge solenoid valve manufacturers select robust materials such as stainless steel, hardened steel, or specially treated brass to handle high pressures and abrasive fluids.

The coil housing is typically designed to resist moisture, vibration, and temperature changes, protecting the valve's internal components. By combining strong materials with tight manufacturing tolerances, these valves maintain stable performance across thousands of operating cycles. This attention to detail helps reduce maintenance frequency and extends the service life of both the valve and the system it supports.

Energy Efficiency and Easy Maintenance

Another advantage of a cartridge solenoid valve lies in its energy-saving design. Modern coils are engineered for low power consumption while maintaining reliable magnetic force. This feature supports mobile equipment or battery-powered systems that need efficient operation without constant power draw.

Maintenance is also simpler. Because the valve is built into a cartridge format, it can be easily removed and replaced without disturbing the entire hydraulic block. This modularity saves time during servicing and reduces downtime- a major benefit for industrial users who value productivity.

Choosing the right cartridge solenoid valve manufacturers can make a noticeable difference in system performance and long-term reliability. When sourcing, it's worth considering:

Technical Capability: Look for manufacturers who provide clear performance data, CAD models, and testing details.

Quality Control: Consistency in machining and assembly directly affects how well a valve seals and responds during operation.

As automation and hydraulic technologies evolve, the cartridge solenoid valve continues to be a trusted component for compact and efficient fluid control. The attention to detail shown by dedicated cartridge solenoid valve manufacturers- from material choice to precision assembly- allows engineers to build systems that perform reliably in the field. For businesses focused on stable performance and easy maintenance, choosing the right partner in this industry can bring lasting value.

EN

EN English

English Español

Español