Stable water control is a common demand across industries such as home appliances, sanitary ware, irrigation, food equipment, and automated supply systems. Many users approach us because they struggle with valves that fail early, react slowly, or cannot handle frequent switching. These issues disrupt production and increase maintenance work.

Our factory specializes in bi-stable pulse solenoid valves for intelligent toilets and sanitary devices. Over time, customer demand expanded, and so did our technical capability. Today, our water solenoid valve products support not only sanitary ware but also smart water meters, washing equipment, garden irrigation devices, and industrial control systems.

1. Product Performance Designed for Long Working Cycles

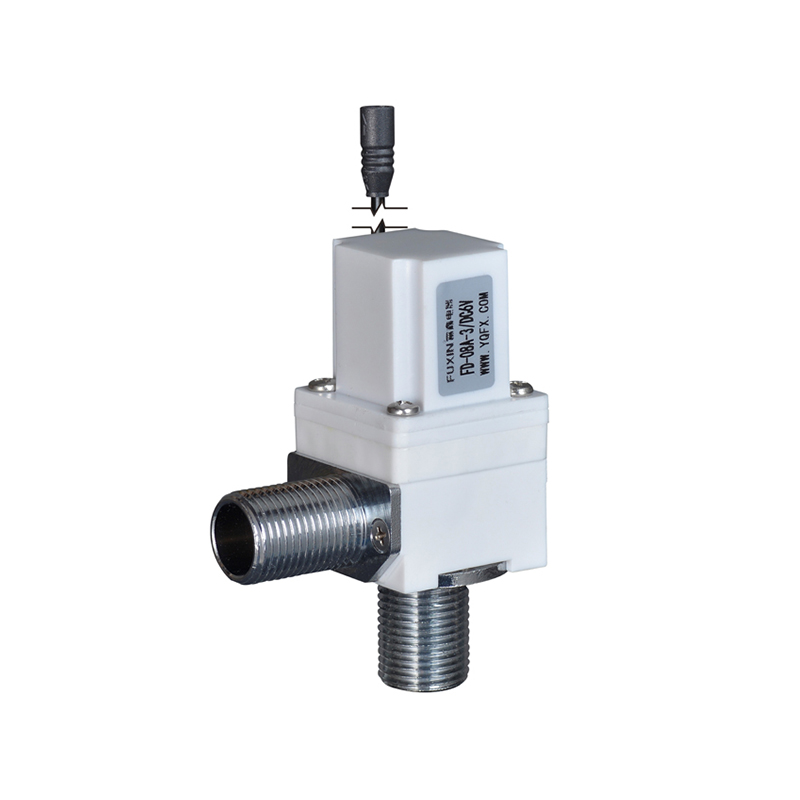

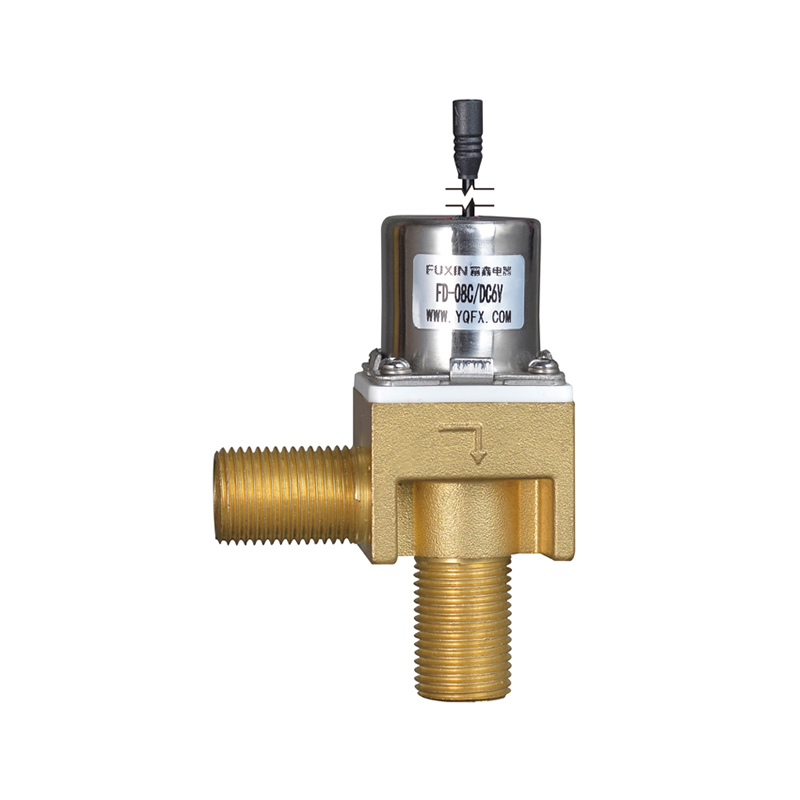

A water solenoid valve must maintain stable action even under frequent switching. Many customers worry about coil burnout, sealing wear, and inconsistent opening force. To answer these pain points, our engineering team focuses on coil stability, precise machining, and strong sealing structures.

Our internal testing labs play an important role. Each valve model goes through performance checks, temperature variation tests, and durability evaluations that simulate real-world use. Many products reach a service cycle far beyond one million operations, which helps users avoid early replacement costs. As water solenoid valve manufacturers with long production experience, we understand how much routine failures interrupt business operations, so lifespan development is a constant part of our work.

2. Production Capacity Built for OEM and Large-Scale Requirements

As the market grew, Fuxin invested heavily in expansion. In 2009, we built an industrial center in Chongqing covering 18,000㎡ and added great workshops for injection molding, stamping, machining, polishing, coil production, and assembly. The facility supports a stable supply for clients who require continuous delivery throughout the year.

OEM customers often request customized specifications or matching accessories. Our in-house design teams and specialized workshops make it possible to adjust materials, connector types, flow parameters, and coil configurations. Water solenoid valve manufacturers that serve OEMs must deliver consistent quality, and our production system is structured so that every link—from molding to final testing—follows controlled processes handled by trained technicians.

3. Certifications and Global Market Development

Reliability is important not only in performance but also in compliance. Fuxin products have passed ISO9001 quality system certification along with CE, ROHS, ACS, CB, KTW, W270, and NSF standards, depending on the model and application. These certifications support customers who sell to markets with strict approval requirements.

With an annual output reaching several million units, our products are supplied to well-known sanitary ware companies and exported to more than 20 regions, including the United States, Canada, Germany, Brazil, Russia, and Singapore. This broad market experience helps us understand varied installation habits, voltage systems, and application environments, which feed back into new product development.

4. Support for Smart and Automated Water Systems

As automation becomes more common, many clients need a water solenoid valve that reacts quickly, uses energy efficiently, and integrates into compact devices. Our pulse-type and conventional valves are widely used in intelligent toilets, smart water meters, small appliances, and solar water control systems. The valve structure is designed for stable movement and low energy demand, helping equipment operate smoothly without complicated maintenance routines.

Water solenoid valve manufacturers must adapt to the needs of new devices that require quiet operation, smaller sizes, and stable switching. With dedicated research teams and a testing center equipped with great tools such as life-cycle machines, salt spray chambers, and oscilloscope instruments, we continue refining both the structure and operation of the valve body.

EN

EN English

English Español

Español