Modern irrigation projects demand stable water flow, simple automation, and components that keep working season after season. Many users struggle with valves that jam, consume too much power, or require frequent replacement. These problems interrupt watering schedules and add cost to landscape maintenance. As long-term irrigation solenoid valve manufacturers, we focus on addressing these daily frustrations with products built for durability, usability, and stable performance.

Our irrigation solenoid valve line was developed to help residential gardens, greenhouses, and commercial landscapes achieve smooth operation without complicated adjustments. Each valve is produced in our dedicated workshops, where teams concentrate on structure design, material selection, and testing procedures that simulate outdoor conditions. By understanding real user challenges, we continually refine how our valves respond to changing pressure, temperature shifts, and long watering cycles.

1. Built for Consistent Operation in Garden and Landscape Systems

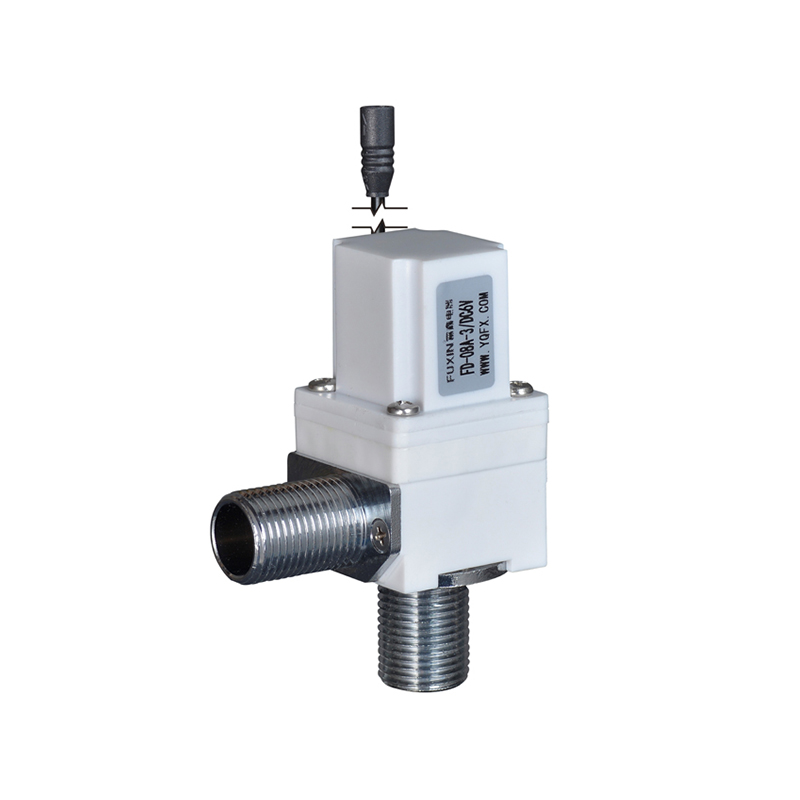

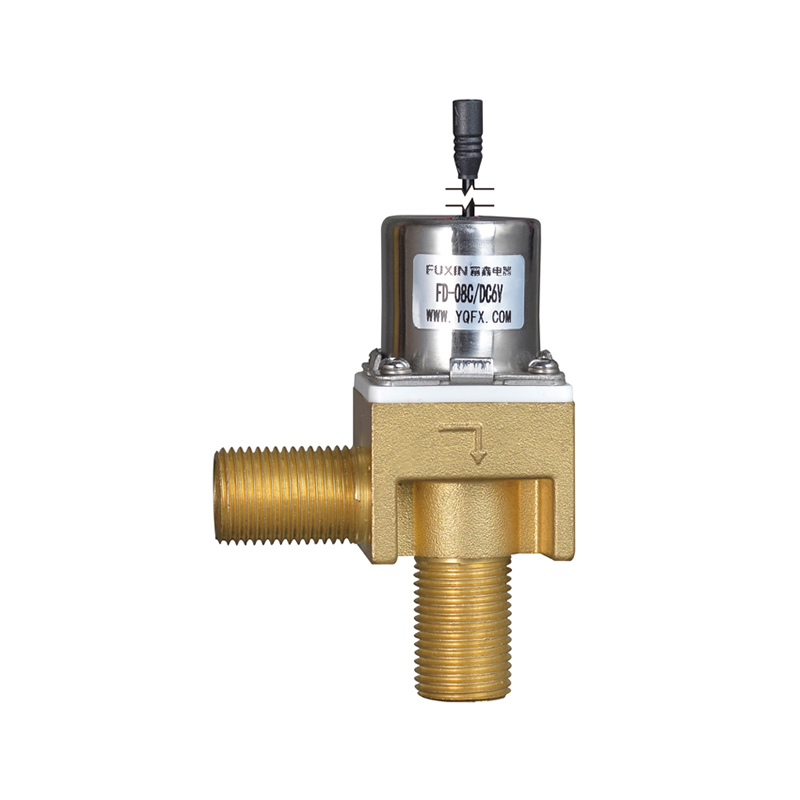

An irrigation solenoid valve must operate reliably even when exposed to dirt, moisture, and temperature swings. Users often complain about valves sticking during peak irrigation seasons or losing responsiveness after months of use. To reduce these issues, our engineering team focuses on corrosion-resistant materials and steady coil performance. Internal components are built to handle repeated cycles without losing force or slowing down.

Through testing chambers that expose valves to extended operation, humidity, and variable pressure settings, we develop products that maintain stable control signals. This gives users confidence that watering schedules will continue without unexpected disruptions. As irrigation solenoid valve manufacturers with multi-year experience, we understand that uninterrupted performance directly supports healthier plants and efficient water management.

2. Designed to Lower Energy Use and Reduce Maintenance Tasks

A frequent concern among users is high energy consumption in automated systems. Our irrigation solenoid valve models are engineered with low-power coils and efficient internal structures that require less electricity to activate. This reduces long-term operating costs and supports the growing demand for energy-conscious irrigation setups.

Maintenance is another common pain point. Many landscape technicians prefer components that do not require frequent cleaning or part replacements. Because of the valve's reinforced housing and streamlined flow path, debris buildup is minimized. This helps reduce repair frequency and keeps irrigation networks running longer between service intervals. Technicians appreciate the time saved, especially when managing multiple zones across large properties.

3. Adaptable Solutions for Different Garden and Commercial Layouts

Irrigation systems vary widely, and users need valves that adapt to different flow ranges, installation angles, and pipe sizes. Our production line includes options tailored for small gardens, residential lawns, agricultural beds, and commercial green spaces. Each irrigation solenoid valve is built to work with various controllers and automation devices, helping users upgrade older systems without reworking the entire layout.

As irrigation solenoid valve manufacturers, customization is a significant part of our service. Customers can request variations in flow parameters, body size, connectors, or pressure ratings. These adjustable features allow irrigation planners to match the valve precisely to the needs of each zone, whether it involves drip irrigation, misting systems, or larger sprinklers.

EN

EN English

English Español

Español