Touchless faucet systems have become a standard choice in public restrooms, commercial spaces, kitchens, and healthcare facilities. Many users switch to sensor faucets to solve problems such as frequent contact, water waste, and inconsistent flow control. At the center of these systems is the faucet valve, a component that directly influences response time, durability, and user experience. As long-term faucet valve manufacturers, we develop solutions that support the performance requirements of modern sensor faucets.

Our sensor faucet valve series was created to help faucet producers build reliable products for different environments, from busy public washrooms to private residential kitchens. Through dedicated research and controlled production processes, we focus on delivering valves that handle frequent switching, moisture exposure, and long service cycles without performance loss.

1. Designed for Long-Term Use and Reliable Daily Operation

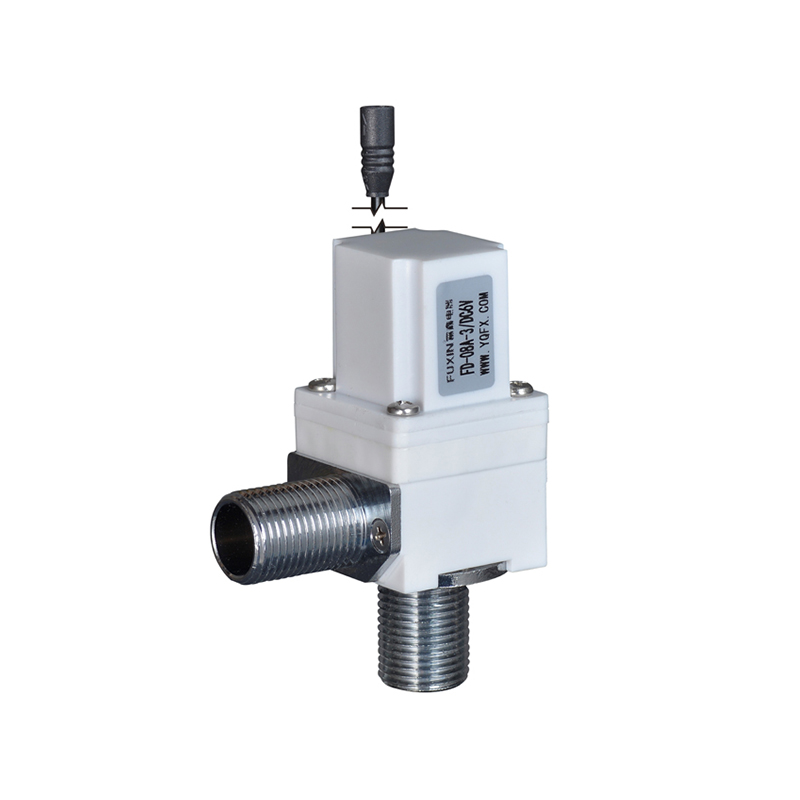

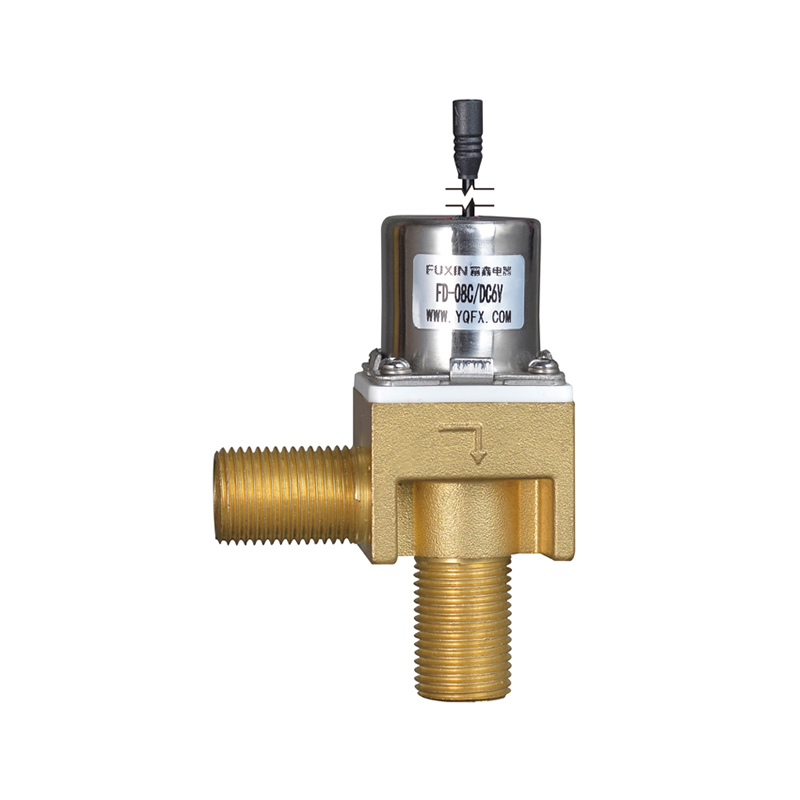

A faucet valve must sustain constant activation, especially in locations with heavy traffic. Many customers face issues such as slow response, clogging, or decreased flow after months of continuous operation. To address these concerns, we build our valves with reinforced structures and great internal components that keep performance stable over extended cycles.

The valves are designed to reach up to 1.2 million operations, which greatly reduces the need for frequent replacement. Our testing procedures expose each model to pressure variations, humidity, and repeated on-off cycles to evaluate long-term behavior. As faucet valve manufacturers with strong technical backgrounds, we understand how reliability directly affects sanitation standards and user trust.

2. Low Power Consumption for Modern Sensor Applications

Touchless faucet systems often run on battery power. A key concern for manufacturers and installers is the frequent replacement of batteries, especially in public facilities. Our faucet valve technology supports low-power operation through pulse-signal activation, which requires only a short electrical signal. This reduces the load on batteries and supports stable performance even in compact faucet structures.

For installations with a direct electrical connection, the valves also support continuous operation. This flexibility allows engineers to select the mode that fits their system design. Reduced power draw not only lowers operational cost but also contributes to long-term stability in unattended environments.

3. Strong Waterproof Protection and Resistance to Impurities

Sensor faucet installations face constant moisture exposure. A faucet valve with weak protection may fail quickly due to water ingress. To avoid these failures, our valves are designed with a high waterproof rating, supporting strong resistance in wet environments such as bathrooms and kitchens.

The self-cleaning function helps the valve stay clear of impurities that often cause a performance drop in traditional valve structures. This lowers the frequency of maintenance and helps installers avoid repeated service work. For faucet valve manufacturers, these features are important because they directly reduce long-term service demands for our customers.

The use of a ceramic valve core gives stable water regulation, steady temperature control, and resistance to wear. These characteristics are useful in both residential and commercial settings, where consistent performance is required.

Applications extend across public restrooms, home kitchens, healthcare environments, and any setting where touchless control is desired. Users benefit from hands-free operation, reduced germ transmission, and stable water flow supported by a dependable faucet valve.

EN

EN English

English Español

Español