When people hear the term solenoid coil, they often picture a small, unremarkable part tucked inside a piece of machinery. Yet this compact component quietly drives countless systems - from water valves to industrial automation equipment. Behind every reliable coil, there's a group of solenoid coil manufacturers combining material science, engineering precision, and user-focused design to create performance that lasts.

But what exactly makes a solenoid coil stand out? What are users really curious about when they look for one? Let's explore the key factors that many buyers care about and how manufacturers respond to them.

1. Stability and Consistency Under Pressure

One of the early things users wonder is: Will it work the same every time? Whether in a dishwasher, vending system, or fluid control line, the solenoid coil must stay stable even under changing pressure or temperature. Reliable solenoid coil manufacturers build their coils to operate consistently, avoiding random failures or power fluctuation issues.

This stability often comes from precise winding, proper insulation, and the use of durable materials like stainless steel and high-grade plastics. These materials reduce internal wear and allow the coil to respond quickly - sometimes in less than half a second - even after thousands of cycles.

2. Compact Size Meets Practical Design

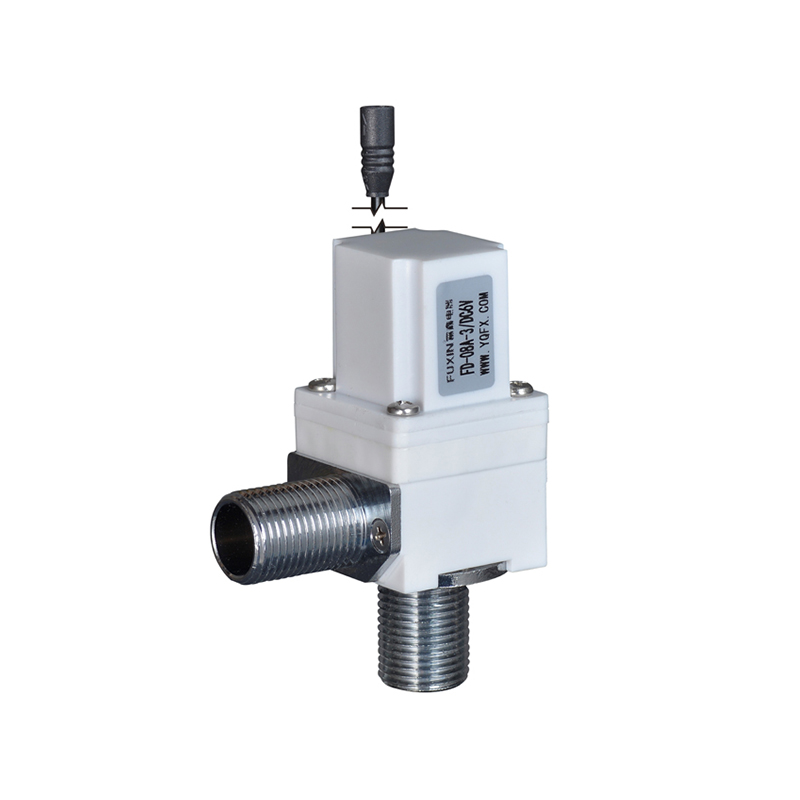

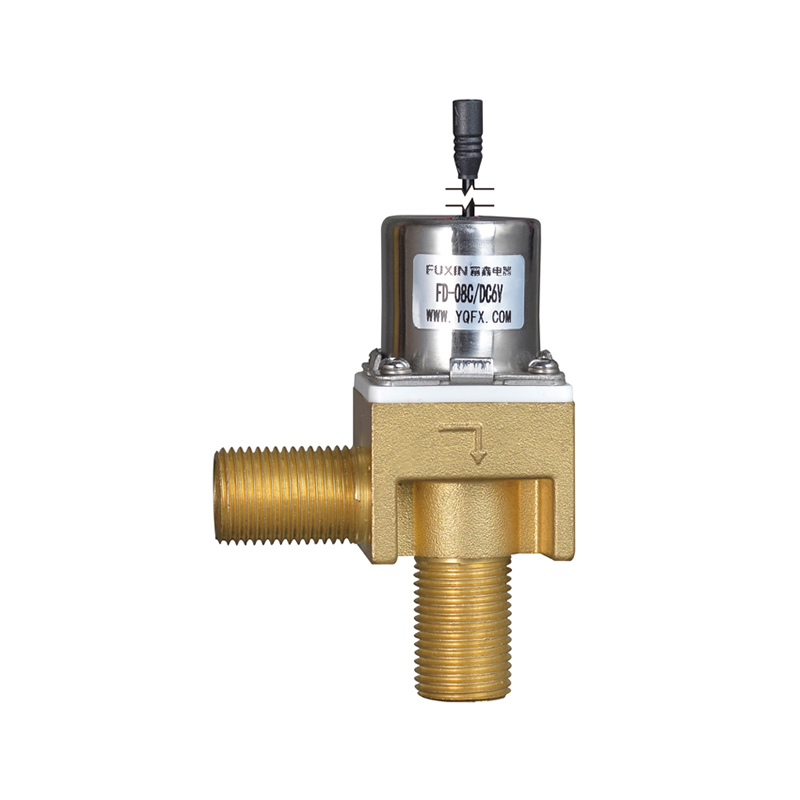

Another common question: How can something so small handle so much work? The beauty of a well-designed solenoid coil lies in its balance between power and compactness. Manufacturers today pay attention not just to performance, but also to how the coil looks and fits into a system.

Some coils now feature a round control head that gives a neat, elegant appearance, which helps equipment makers maintain clean designs. It's a small touch that adds both practicality and visual appeal. For engineers dealing with tight installation spaces, a compact coil can make the difference between a simple setup and a frustrating redesign.

3. Customization for Real-World Applications

Every industry has unique challenges - water flow control, pneumatic actuation, fluid isolation, or electronic locking. This leads buyers to ask: Can I get a solenoid coil that fits my exact need? The answer from modern solenoid coil manufacturers is increasingly “yes.”

Customization is now a standard service rather than a luxury. Buyers can specify the voltage (DC6V, DC12V, or DC24V), structure type, or even response timing to match their system. This flexibility saves integration time and helps achieve smooth operation without extra adjustments. It's a practical solution for engineers who need precise performance without compromising durability.

4. Longevity and After-Sales Support

Users often think long term: How long will it last? What happens if something goes wrong? A high-quality solenoid coil can operate for hundreds of thousands of cycles - sometimes over a million - with little maintenance. That's not just due to materials but also to how solenoid coil manufacturers test their products.

Each unit usually goes through pressure, voltage, and leakage testing under different conditions to confirm it can handle both high and low pressure scenarios. And it doesn't stop after production. Responsible manufacturers provide support through every stage - from choosing the right model to after-sales service - giving users confidence that they're not alone after installation.

The solenoid coil may not be the biggest part of a system, but it plays a central role in keeping operations running smoothly. Today's solenoid coil manufacturers understand that performance, adaptability, and durability matter more than ever.

EN

EN English

English Español

Español