If you've ever wondered how modern appliances like automatic faucets in public restrooms, smart toilet flush systems, or even the precise drip irrigation in a modern greenhouse manage to be so compact, efficient, and reliable, the answer often lies in a deceptively simple component: the cartridge solenoid valve. As a writer with a deep focus on industrial and electromechanical components, I find these valves particularly fascinating. They represent a brilliant convergence of clever engineering and practical, user-centric design, solving persistent problems of space, maintenance, and system complexity. So, what fundamentally sets them apart from their traditional counterparts, and why might they be the fine choice for your next application?

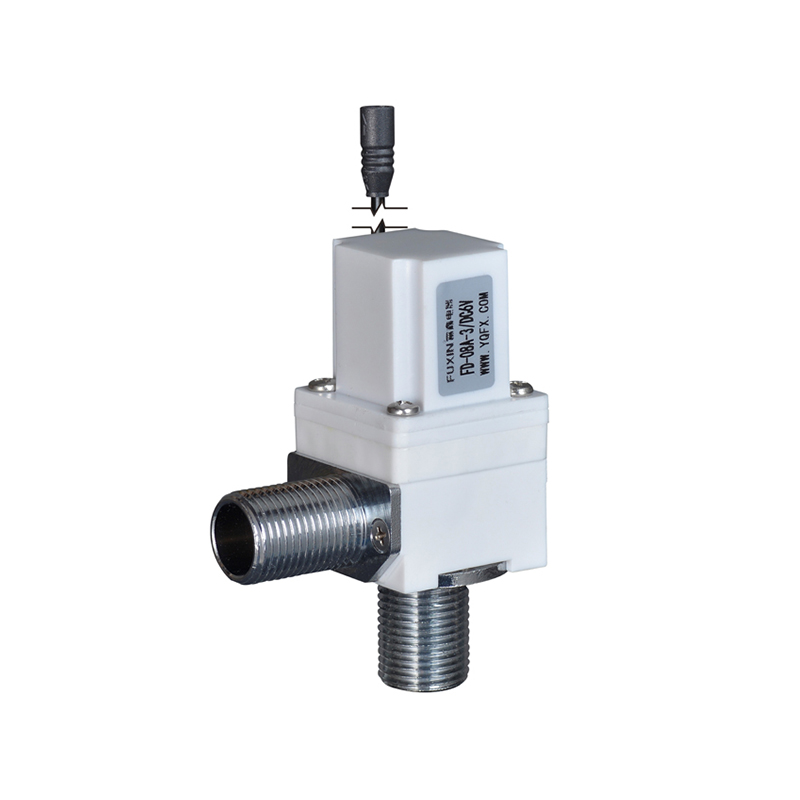

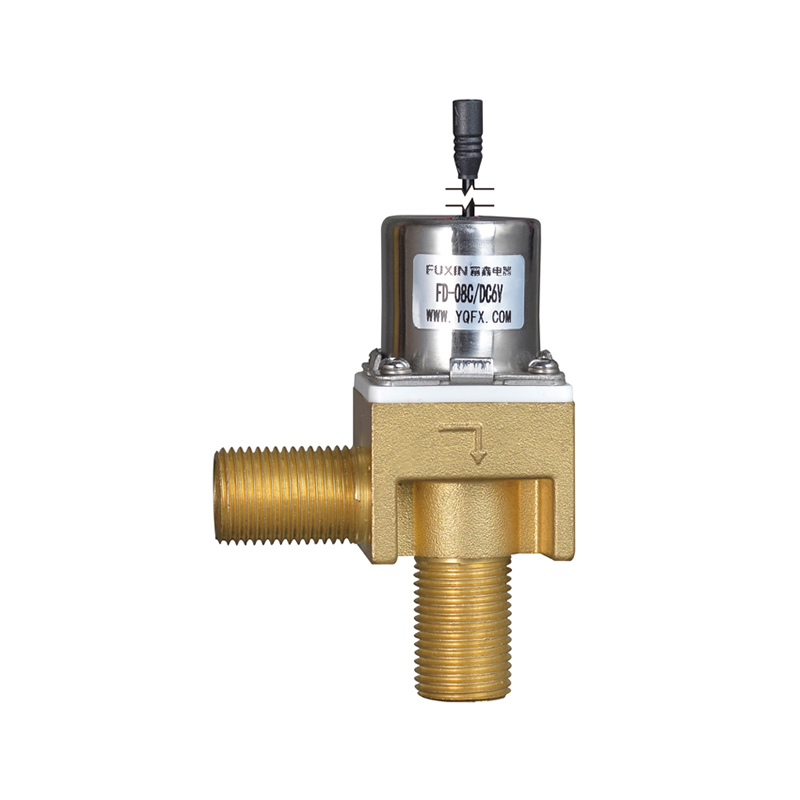

At its core, a cartridge solenoid valve is a self-contained, integrated valve assembly designed to be inserted into a specially machined cavity or manifold block. The apt analogy is indeed a printer cartridge – it's a pre-assembled, fully functional unit that slides neatly into a designated housing, making installation, replacement, and upgrades remarkably straightforward. This innovative design philosophy eliminates the traditional web of multiple external connections, elbows, and piping, resulting in a significantly cleaner, more compact, and inherently more leak-resistant system layout. Unlike traditional inline valves that come with their own external ports, mounting brackets, and require extensive plumbing, the cartridge type integrates directly and seamlessly into the very structure of the equipment it serves, becoming a fundamental part of the machine's architecture.

The practical advantages of this integrated design become profoundly apparent in two key areas: maintenance and overall system performance. Because the cartridge solenoid valve is a self-contained, modular unit, servicing is revolutionized. Imagine a scenario on a food processing line where a valve fails. Instead of a technician spending hours disassembling sections of plumbing, tracing pipes, and struggling with seized fittings, they can simply isolate the manifold, unscrew the faulty cartridge, and insert a new one. This "plug-and-play" approach can reduce downtime from hours to minutes, a critical factor in high-throughput commercial and industrial settings like processing plants, automated irrigation systems, or medical device operations. Furthermore, the compact, cylindrical nature of these valves makes them the undisputed champion for applications where real estate is at a premium. You'll find them nestled inside the tight confines of smart water meters, under-sink reverse osmosis systems, and within the sleek bodies of commercial espresso machines and dialysis equipment.

When considering the sourcing of these components, collaborating with a specialized and reputable cartridge solenoid valve Manufacturer yields benefits that extend far beyond the simple procurement of a physical product. Established manufacturers with strong application engineering support are invaluable partners. They don't just sell a valve; they help you select the precise specifications for your unique needs—considering factors like flow rate (Cv), pressure requirements, fluid compatibility (be it water, air, oil, or a mild chemical), and electrical parameters (AC or DC voltage, coil class). A proficient cartridge solenoid valve Manufacturer will typically offer a range of options with different orifice sizes, seal materials like NBR, EPDM, or FKM (Viton), and a variety of voltage and power options to match a vast spectrum of global applications. Moreover, a credible manufacturer conducts rigorous performance testing—including life cycle tests, pressure decay tests, and burst pressure tests—to verify reliable operation under simulated real-world conditions, providing engineers with added confidence in the product's long-term reliability and durability.

In terms of real-world applications, the versatility of cartridge-style valves is remarkable. They are ubiquitous in medical equipment for controlling air and fluids in ventilators and analyzers, in commercial appliances for dispensing water and beverages, and in water management systems for zone control in irrigation or building water features. Their design allows for direct integration into complex hydraulic or pneumatic manifolds, creating highly streamlined and efficient fluid control systems with drastically fewer potential leak points compared to traditional piped systems. This versatility makes the cartridge solenoid valve adaptable to a dizzying array of industries, from heavy-duty manufacturing and automotive to residential smart home water control.

EN

EN English

English Español

Español