When it comes to dust collector systems and industrial filtration equipment, the pulse solenoid valve plays an important role in maintaining efficient performance. Many users are not fully clear about how to install and position this valve correctly, which can affect the overall operation. Below, we answer some of the common installation questions to help you better understand the correct use of a pulse solenoid valve.

How should a pulse solenoid valve be installed?

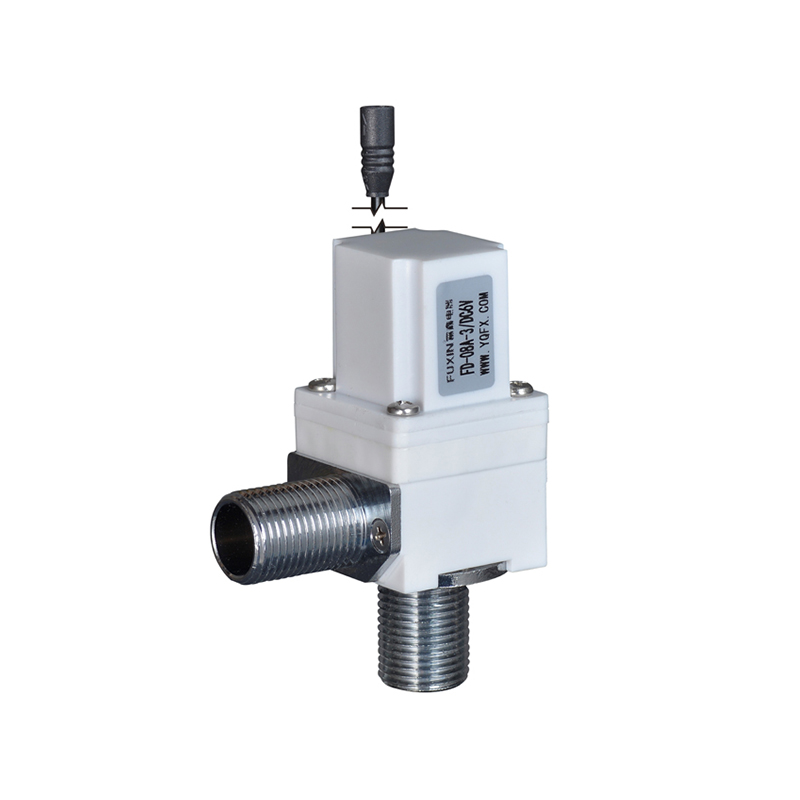

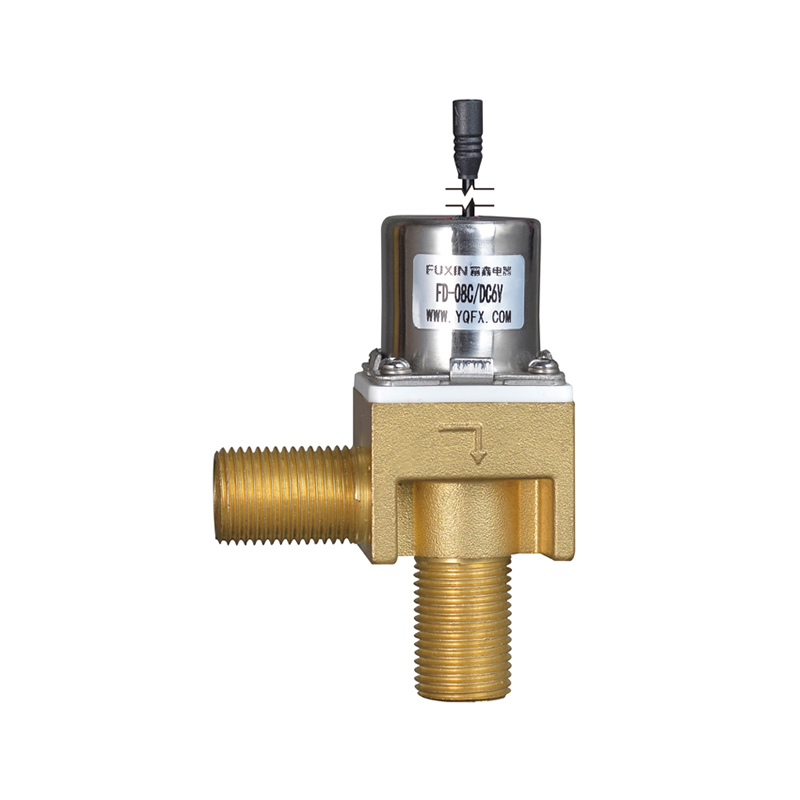

A pulse solenoid valve should be installed firmly onto the compressed air manifold or airbag of the dust collector. The inlet port connects with the compressed air source, and the outlet port connects with the injection pipe to the filter bags. To ensure stable operation, the valve must be installed close to the manifold to reduce air flow resistance. During installation, always keep the O-rings and sealing surfaces clean, as dust or oil contamination may cause leakage. Proper torque should be applied to bolts to avoid deformation of the valve body.

Should the pulse solenoid valve be installed horizontally or vertically?

In applications, a pulse solenoid valve can be installed either horizontally or vertically, depending on the design of the dust collector system. However, the coil should generally remain in an upright position to reduce mechanical stress and improve service life. When space is limited, vertical installation may be used, but it is important to confirm that the diaphragm and coil remain stable. The orientation does not usually affect the air pulse function as long as the airflow direction is correct, but following the manufacturer’s recommendation is always the practice.

How can you tell the correct flow direction of a pulse solenoid valve?

The pulse solenoid valve has a marked inlet and outlet, usually indicated by arrows or letters on the valve body. The inlet is connected to the compressed air tank, while the outlet is connected to the blow tube. Installing the valve in reverse can prevent the diaphragm from working correctly, to poor dust cleaning performance. Before installation, carefully check the direction marking on the valve body. If no marking is visible, refer to the technical datasheet or test the airflow manually to confirm the correct orientation.

What should be noted during the installation of a pulse solenoid valve?

There are several key points to remember when installing a pulse solenoid valve:

- Clean air supply—Ensure the compressed air is clean and dry to avoid diaphragm wear.

- Proper sealing—Check the gaskets and O-rings before installation to prevent leakage.

- Electrical connection—Confirm that the solenoid coil matches the specified voltage, such as AC220V or DC24V, and ensure safe wiring.

- Tightening sequence – Tighten the bolts evenly to avoid stress on the valve body.

- Regular inspection—After installation, test the valve by applying short pulses to make sure it opens and closes smoothly.

By following these guidelines, the pulse solenoid valve can achieve stable operation, extend its service life, and improve the efficiency of the dust removal system.

The correct installation of a pulse solenoid valve is essential for the stable operation of dust collectors and filtration systems. Understanding how to position the valve, identify the flow direction, and follow installation precautions helps avoid common issues such as air leakage, poor pulse cleaning, or diaphragm damage. By paying attention to details during installation, you ensure that the pulse solenoid valve delivers reliable performance in demanding industrial environments.

EN

EN English

English Español

Español