A Water Solenoid Valve is an electromechanical component designed to open or close water flow through electrical control. Once energized, the solenoid creates a magnetic force that moves an internal plunger. This movement either allows water to pass or blocks the flow, depending on the valve design. This process happens quickly and repeatedly, which suits systems that require regular and controlled water delivery.

In sanitary ware environments such as faucets, showers, and toilets, controlled water flow supports a consistent user experience. The valve responds directly to electrical signals from sensors, switches, or control boards. This makes it suitable for touch-free fixtures and automated water systems where manual operation is not practical.

Because water quality and usage patterns vary across regions, a Water Solenoid Valve Manufacturer often designs valves that can adapt to different pressure ranges and operating cycles. This adaptability allows the valve to function steadily in residential, commercial, and light industrial environments.

Addressing Common Concerns in Water Control Systems

System designers often face issues like leakage, unstable flow, or inconsistent response during long-term operation. A Water Solenoid Valve helps address these points by offering direct and repeatable control over water movement. Sealing structures are designed to limit internal seepage, while precision components help maintain consistent opening and closing behavior.

Power usage is another concern, especially in appliances and sanitary fixtures that operate multiple times a day. Modern designs focus on efficient electromagnetic structures that maintain performance without unnecessary electrical load. This approach supports steady operation in washing machines, dishwashers, and water purification units.

Noise during operation is also a consideration in indoor environments. A well-designed Water Solenoid Valve uses balanced internal movement to reduce vibration and mechanical impact. This helps maintain a quiet operating experience in homes, hotels, and offices where comfort matters.

Materials and Manufacturing Design Choices

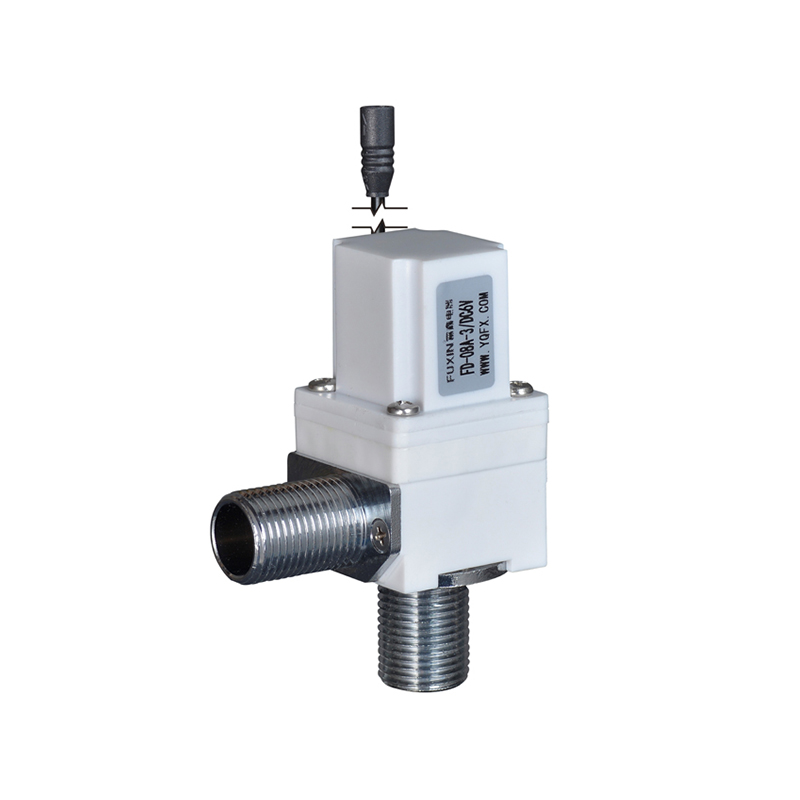

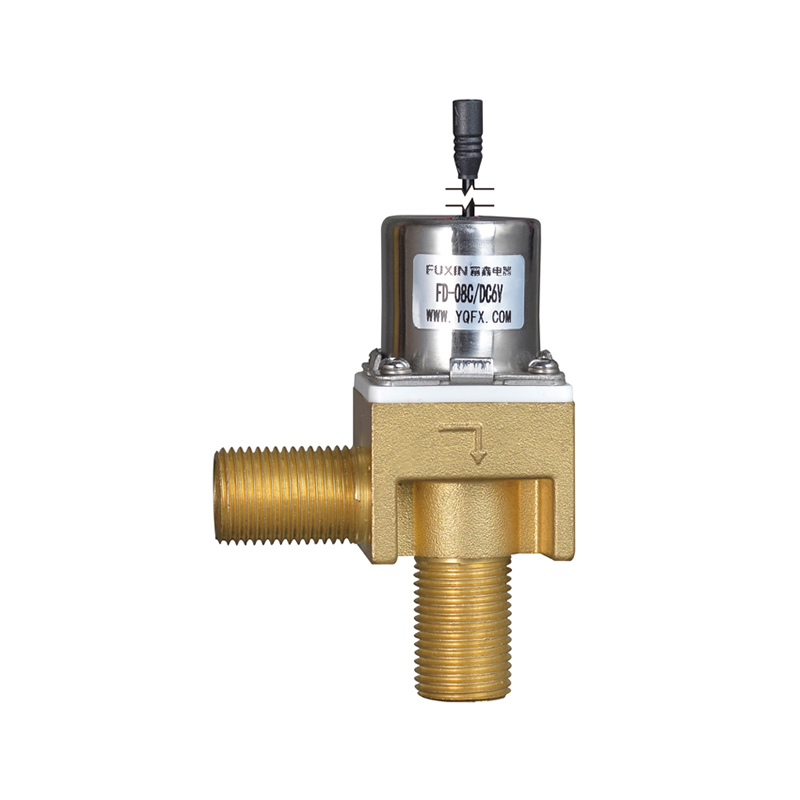

Material selection directly affects how a Water Solenoid Valve performs over time. In sanitary and household applications, resistance to corrosion and wear is important. Common materials include stainless steel, brass, and engineered plastics, each selected based on contact with water, temperature variation, and pressure conditions.

From a production perspective, a Water Solenoid Valve Manufacturer focuses on machining accuracy and assembly consistency. Small variations in internal dimensions can influence flow behavior, so precise manufacturing processes are used to maintain uniformity across production batches. Coil winding quality also plays a role, as it affects how the solenoid responds to electrical input during repeated cycles.

Manufacturers serving multiple industries often offer options in voltage, port size, and connection type. This allows the same basic valve concept to be applied in sanitary ware, household appliances, and irrigation systems without redesigning the entire structure.

A reliable Water Solenoid Valve Manufacturer also provides guidance during the installation and testing stages. Clear documentation and responsive technical support help reduce adjustment time and support smooth integration into water control systems.

Through stable operation, adaptable design, and practical installation features, a Water Solenoid Valve continues to play a key role in modern water management. Its ability to support controlled flow across sanitary ware, household appliances, and irrigation systems makes it a valuable component in many everyday and engineered applications.

EN

EN English

English Español

Español